Description

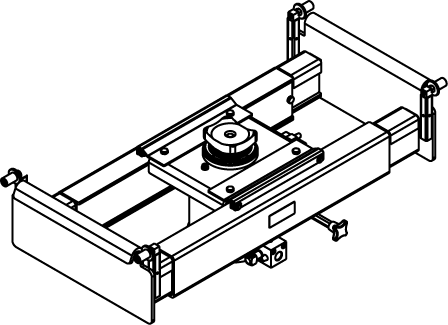

- Complete: Two extensions and a middle support are part of the standard kit. They are ready to hand being fitted directly to the lift.

- Smooth running: The standard needle roller bearings on the carriage rollers permit effortless sliding of the lift inside the pit.

- Time-saving: The mechanical forced return rapidly retracts the piston even when off-load. Unlike conventional pit lifts, the piston is in effect ”pulled” back into its rest position.

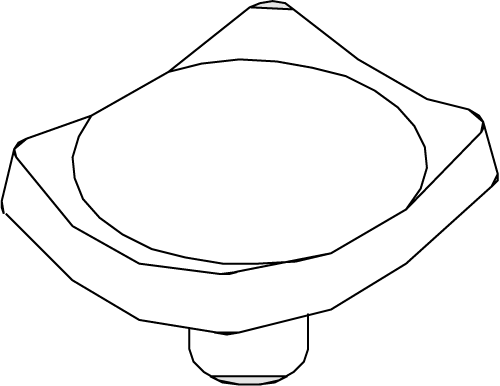

- Precision: The stepless fine-adjustment stroke permits the pit lift to be positioned accurately at the vehicle. Important for responsive lifting and when offering up assemblies.

- Minimum effort: The load stroke of the pneumatic motor enables the load to be lifted at the push of a button – without any physical effort.

- Durability: Both the piston rod and the pump piston are hard-chrome plated, for protection against corrosion and wear.

- Load-depressing safety crosstrolley: The movement facility under load is disabled from a load of approx. 800 kg. A particularly flat design is also achieved.

- 1st and 2nd stage each with 14 t load capacity