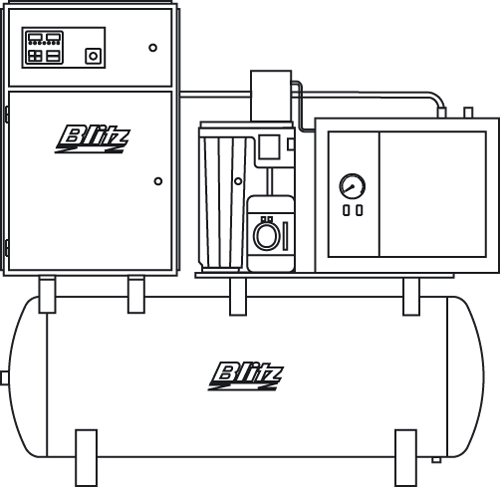

Description

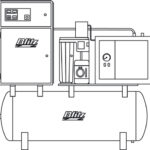

The possible applications of MONSUM screw compressors are almost unlimited and as individual as the available designs. Even the small MONSUN with 4 kW motor rating has the potential of a top performer. The design features and advantages are consistently apparent in all MONSUN models, e.g. the integrated oil sump, the maintenance-friendly openness to all sides and the PROCON control system.

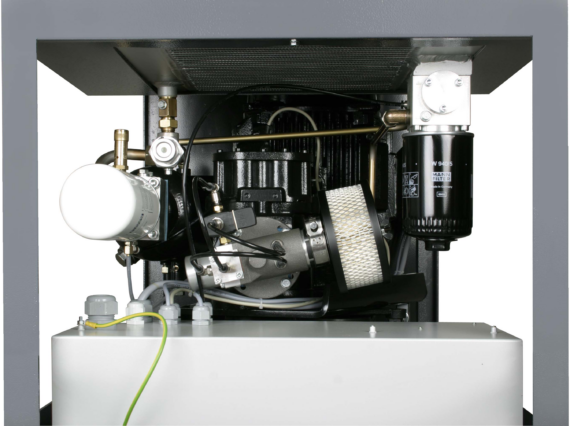

- Soundless: Due to numerous detailed flow dynamic engineering solutions, the operating noise is reduced to a minimum – as a standard.

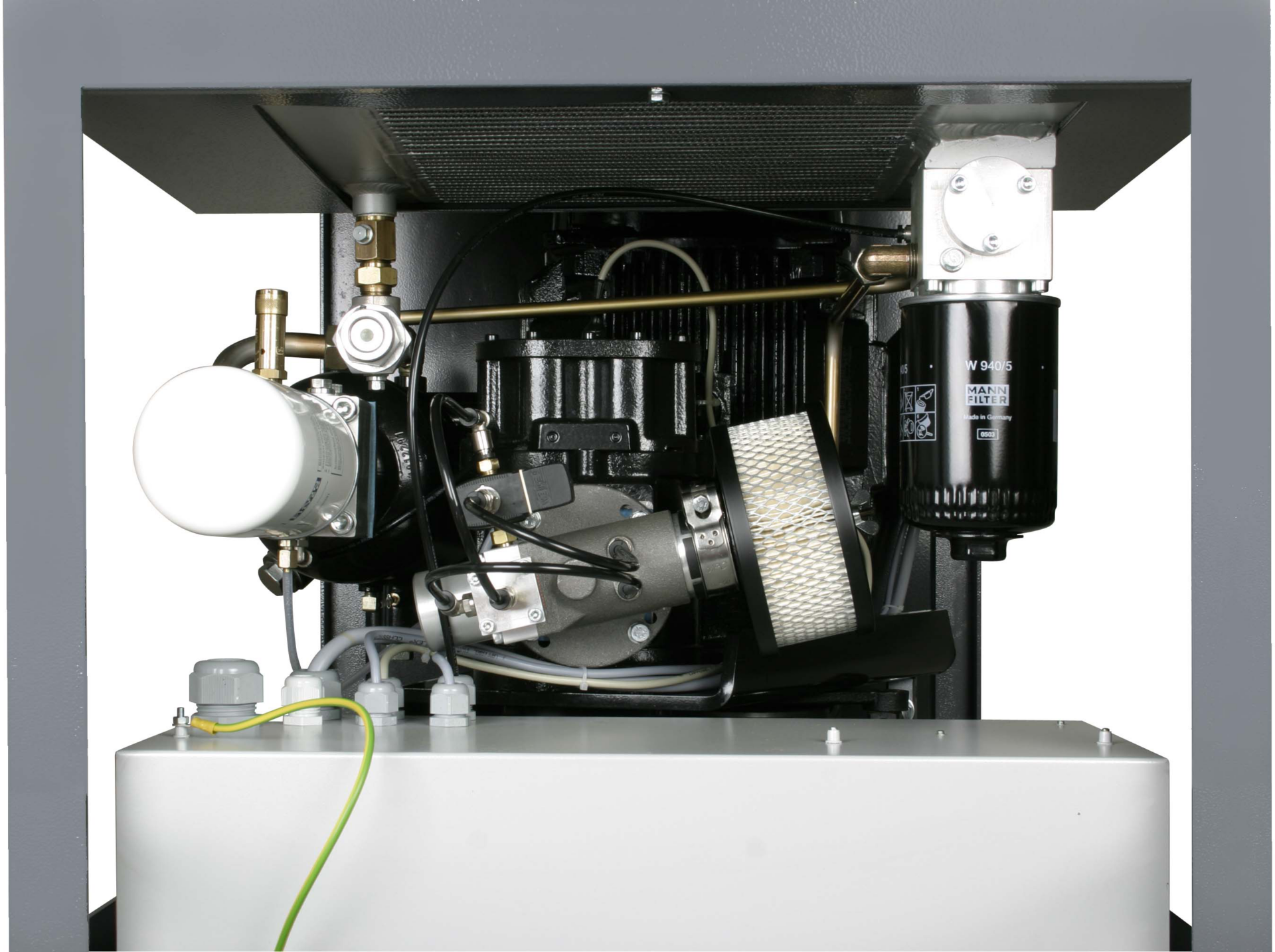

- Two-stage suction filtering: The entry of foreign bodies is prevented by a cyclone separator with a succeeding fine filter.

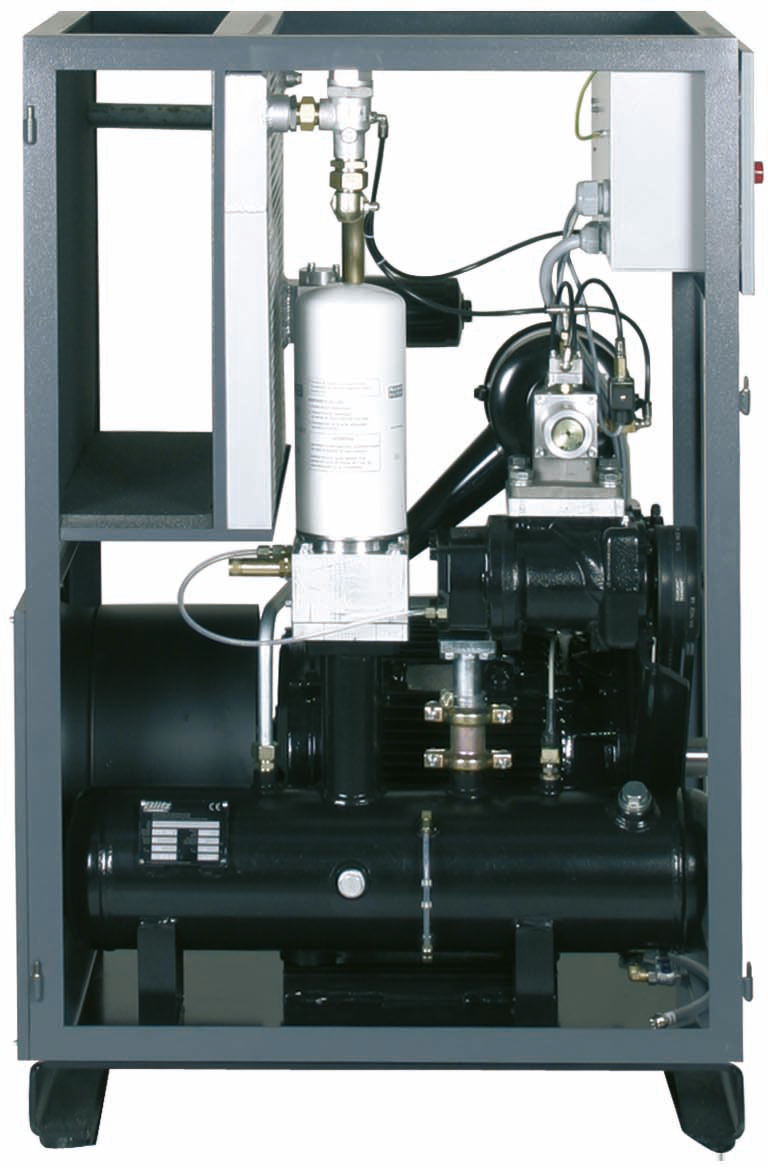

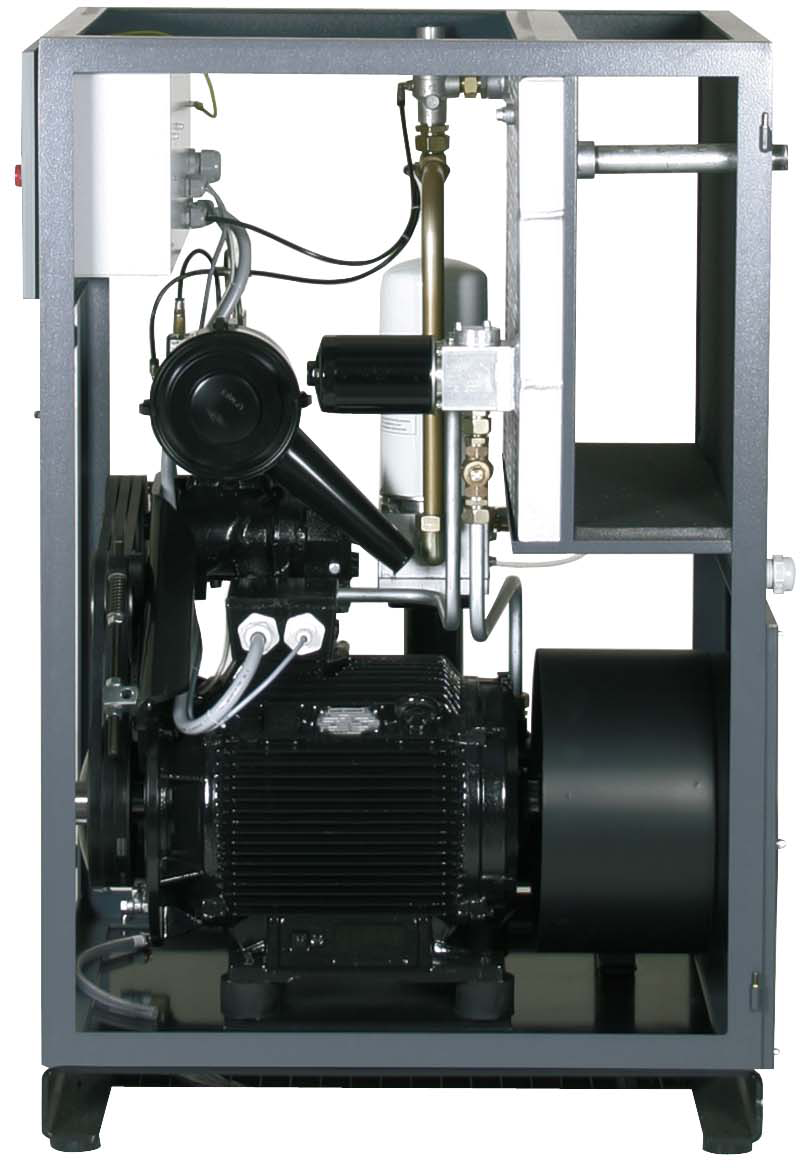

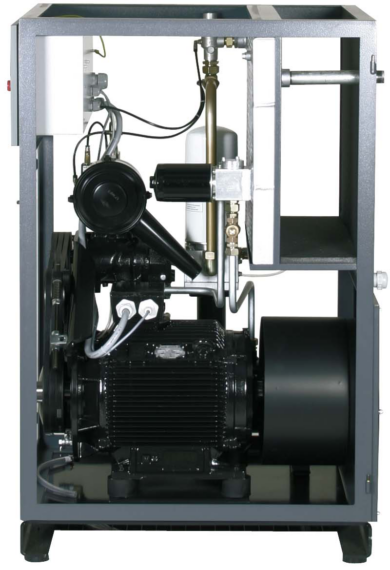

- Equipped for the future: Different pressures can be achieved due to the flexible belt drive. In addition, this facilitates smooth starting, absorbing the ensuing starting torques effectively.

- Drive with reserves: MONSUN screw compressors are manufactured to high standards of quality. This includes the use of IP55 tested motors. The ISO F winding, designed to ISO B, provides power reserves for the worst case.

- Infinite suction control: The use of hard anodised surfaces guarantees the highest durability and control capability. No adjustments are required for BLITZ suction regulators. In conjunction with the optional, proportional controller, a smooth adjustment to the compressed air demand can also be achieved.

- Integrated oil sump: Reliably prevents the unintended escape of used oil to the environment. A supplied hose additionally shortens the time required for necessary oil changes.

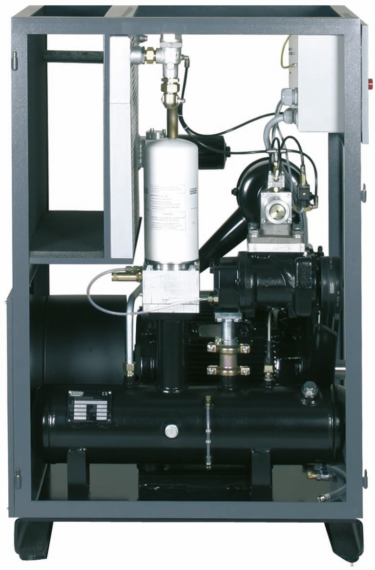

- Three-stage air/oil separation: A cyclone separator, a gravity separator and a filter produce an excellent air quality with a residual oil content of approx. 2 mg/m³.

- Visual oil level indicator: Regular oil checks are often neglected because they are difficult to perform. MONSUN screw compressors provide a clear view in this respect.

- External fine separator: Generously proportioned fine separator inserts reduce undesired, internal pressure losses. They can be changed in just seconds.

- Open in all respects: All side sections are removable in the screw compressors of the MONSUN series. This literally makes child’s play out of maintenance work and reduces stoppage times to a minimum.

- Compact aluminium cooler: The composite design unifies oil and air cooling in a single assembly. Cleaning is made particularly easy by the maintenance-friendly arrangement.

- Permanently piped: You won’t find risky hose connections in BLITZ screw compressors. The novel FLEX piping guarantees a firm attachment in all situations.

- Operating pressures up to 15 bar: The rugged, modular construction of the MONSUN screw compressors makes designs possible from 7.5 to 15 bar.

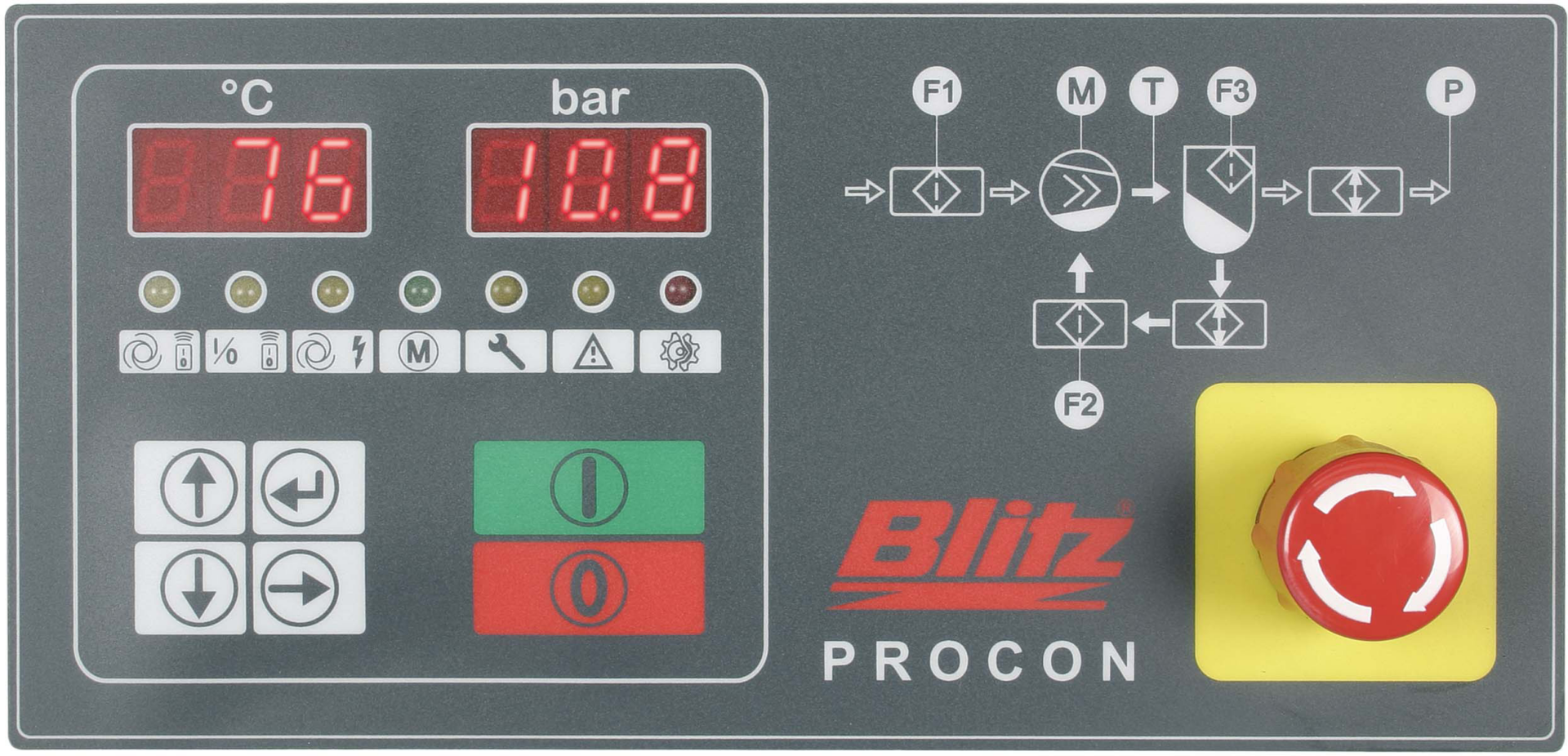

Screw compressors of the MONSUN series are equipped as a standard with an integrated microprocessor control system. PROCON unifies the simplest operation with extraordinary performance features. All settings can be made conveniently on a control panel. Numerous operating modes allow an optimum adjustment to the existing operating conditions.

- An integrated diagnostic system monitors all safety-relevant operating parameters.

- System self-test before each start.

- Service messages indicate outstanding maintenance work (service interval function).

- Automatic start-up after power failures – When the final pressure has been reached, PROCON calculates the actually required run-on time. This saves up to 60 % of energy costs in idle operation.

- The pressure sensor ensures precise operation in the adjusted pressure range (pressure differences of 0.2 bar are possible).

- The motor only runs when necessary in automatic mode. Galvanically isolated contacts make connection to a master control system possible.

- Switchable remote and local operation.

- Electronic base-load change-over function regulated via second pressure band (optional).