Trucks

Showing 298–396 of 494 results

-

Floor-running pit lift Blitz M 20/15 Plus

20/15 t, 1200 mm lift, high speed, operating panel completely covered

-

Floor-running pit lift Blitz M 15/15/15 Plus

15/15/15 t, 1300 mm lift, high speed, operating panel completely covered

-

Floor-running pit lift Blitz M 15/15 Premium

15/15 t, 1200 mm lift, high speed, operating panel completely covered, two-sided operation

-

Floor-running pit lift Blitz M 20/15 Premium

20/15 t, 1200 mm lift, high speed, operating panel completely covered, two-sided operation

-

Floor-running pit lift Blitz M 15/15/15 Premium

15/15/15 t, 1300 mm lift, high speed, operating panel completely covered, two-sided operation

-

Floor-running pit lift Blitz R 15/15 Basic

15/15 t, 1200 mm lift, normal speed

-

Floor-running pit lift Blitz R 20/15 Basic

20/15 t, 1200 mm lift, normal speed

-

Floor-running pit lift Blitz R 15/15/15 Basic

15/15/15 t, 1300 mm lift, normal speed

-

Floor-running pit lift Blitz R 15/15 Plus

15/15 t, 1200 mm lift, high speed, operating panel completely covered

-

Floor-running pit lift Blitz R 20/15 Plus

20/15 t, 1200 mm lift, high speed, operating panel completely covered

-

Floor-running pit lift Blitz R 15/15/15 Plus

15/15/15 t, 1300 mm lift, high speed, operating panel completely covered

-

Floor-running pit lift Blitz R 15/15 Premium

15/15 t, 1200 mm lift, high speed, operating panel completely covered, two-sided operation

-

Floor-running pit lift Blitz R 20/15 Premium

20/15 t, 1200 mm lift, high speed, operating panel completely covered, two-sided operation

-

Floor-running pit lift Blitz R 15/15/15 Premium

15/15/15 t, 1300 mm lift, high speed, operating panel completely covered, two-sided operation

-

Pit lift, suspended GHL 10

10 t, 800 mm stroke, Load stroke hand-hydraulicrnINDIVIDUAL SOLUTIONS rnSpecial rollers and special chassis on request

-

Pit lift, suspended GHL 15

15 t, 800 mm stroke, Load stroke hand-hydraulic

-

Pit lift, suspended GHL 20

20 t, 800 mm stroke, Load stroke hand-hydraulic

-

Pit lift, suspended GHL 30

30 t, 800 mm stroke, Load stroke hand-hydraulic

-

Pit lift, suspended GHUSL 4

Load stroke hand-hydraulic, hydraulic-pneumatic quick lift, hydraulic-neumatic forced return

-

Pit lift, suspended GHUSL 10

Load stroke hand-hydraulic, hydraulic-pneumatic quick lift, hydraulic-neumatic forced return

-

Pit lift, suspended GHUSL 15

Load stroke hand-hydraulic, hydraulic-pneumatic quick lift, hydraulic-neumatic forced return

-

Pit lift, suspended GHUSL 20

Load stroke hand-hydraulic, hydraulic-pneumatic quick lift, hydraulic-neumatic forced return

-

Pit lift, suspended GHUSL 30

Load stroke hand-hydraulic, hydraulic-pneumatic quick lift, hydraulic-neumatic forced return

-

Pit lift, suspended GHUSLP 4

4 t, 800 mm stroke, Load stroke by air motor, hydraulic-pneumatic quick lift, hydraulic-pneumatic forced return

-

Pit lift, suspended GHUSLP 10

10 t, 800 mm stroke, Load stroke by air motor, hydraulic-pneumatic quick lift, hydraulic-pneumatic forced return

-

Pit lift, suspended GHUSLP 15

15 t, 800 mm stroke, Load stroke by air motor, hydraulic-pneumatic quick lift, hydraulic-pneumatic forced return

-

Pit lift, suspended GHUSLP 20

20 t, 800 mm stroke, Load stroke by air motor, hydraulic-pneumatic quick lift, hydraulic-pneumatic forced return

-

Pit lift, suspended GHUSLP 30

30 t, 800 mm stroke, Load stroke by air motor, hydraulic-pneumatic quick lift, hydraulic-pneumatic forced return

-

Pit lift, suspended GHUSTP 15/15

15/15 t, 1200 mm stroke, Load stroke by air motor, hydraulic-pneumatic quick lift, hydraulic-pneumatic forced return

-

Pit lift, suspended GHUSTP 20/15

20/15 t, 1200 mm stroke, Load stroke by air motor, hydraulic-pneumatic quick lift, hydraulic-pneumatic forced return

-

Pit lift, suspended GHUSTTP 15/15/15

15/15/15 t, 1300 mm stroke Load stroke by air motor, hydraulic-pneumatic quick lift, hydraulic-pneumatic forced return

-

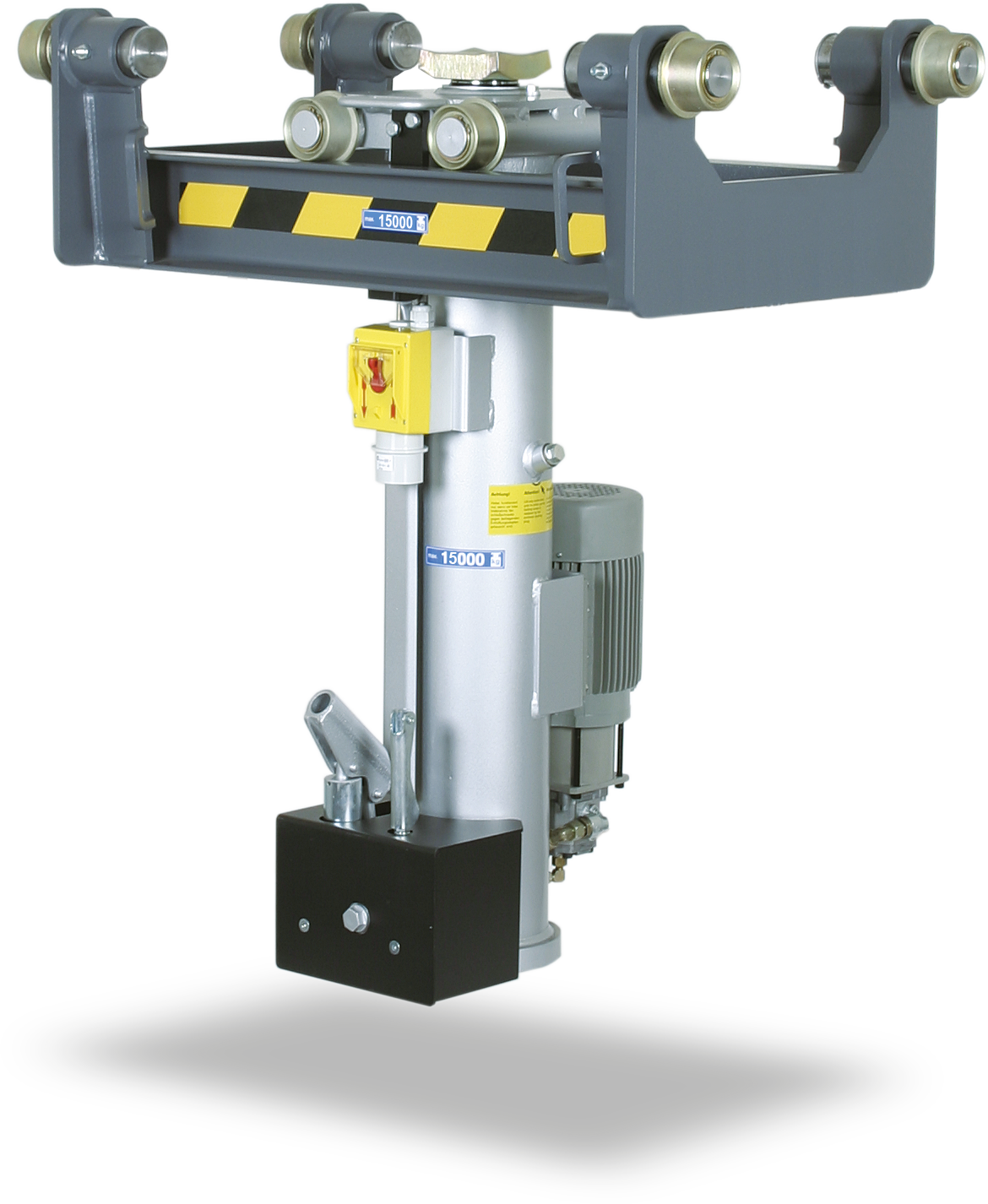

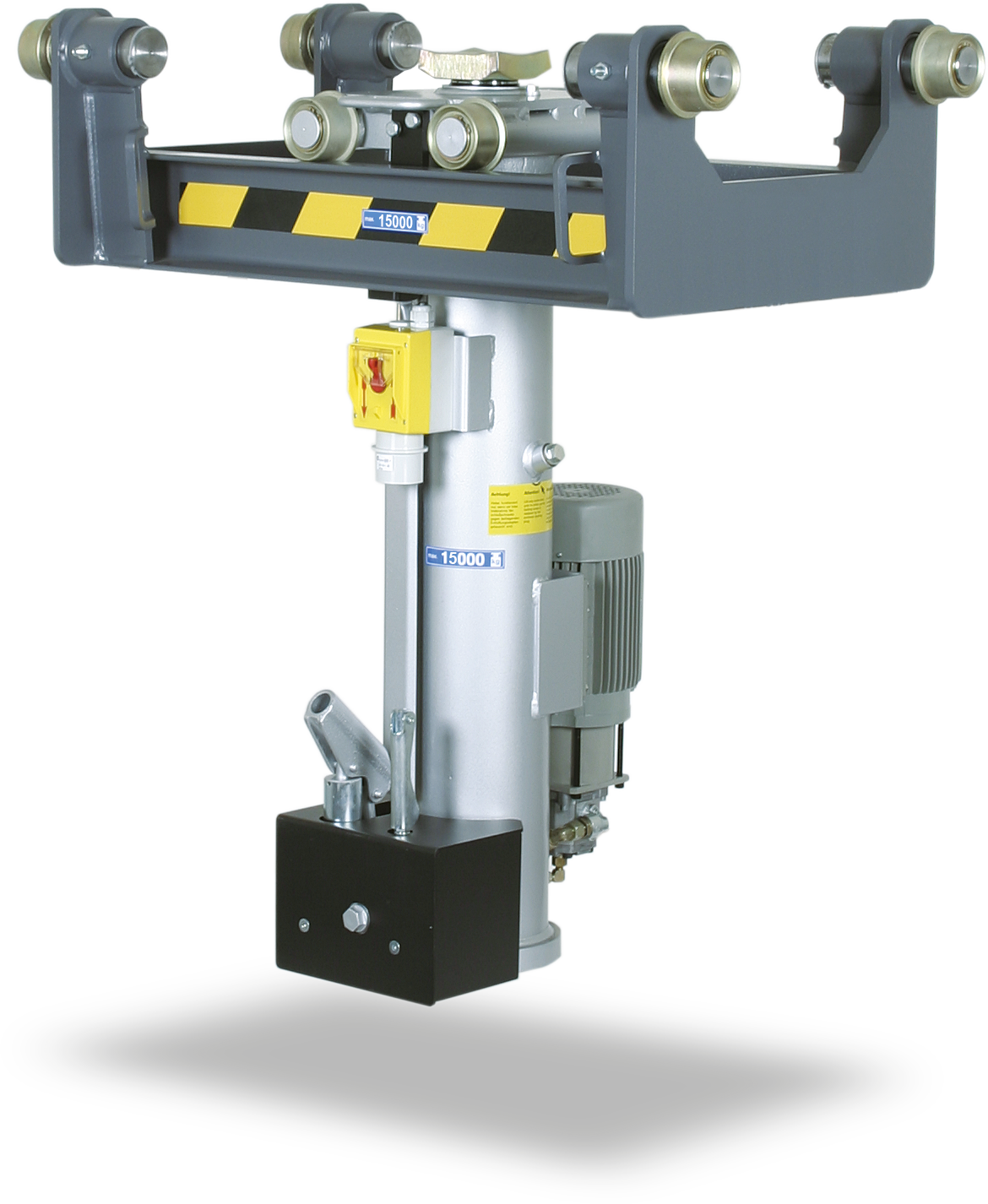

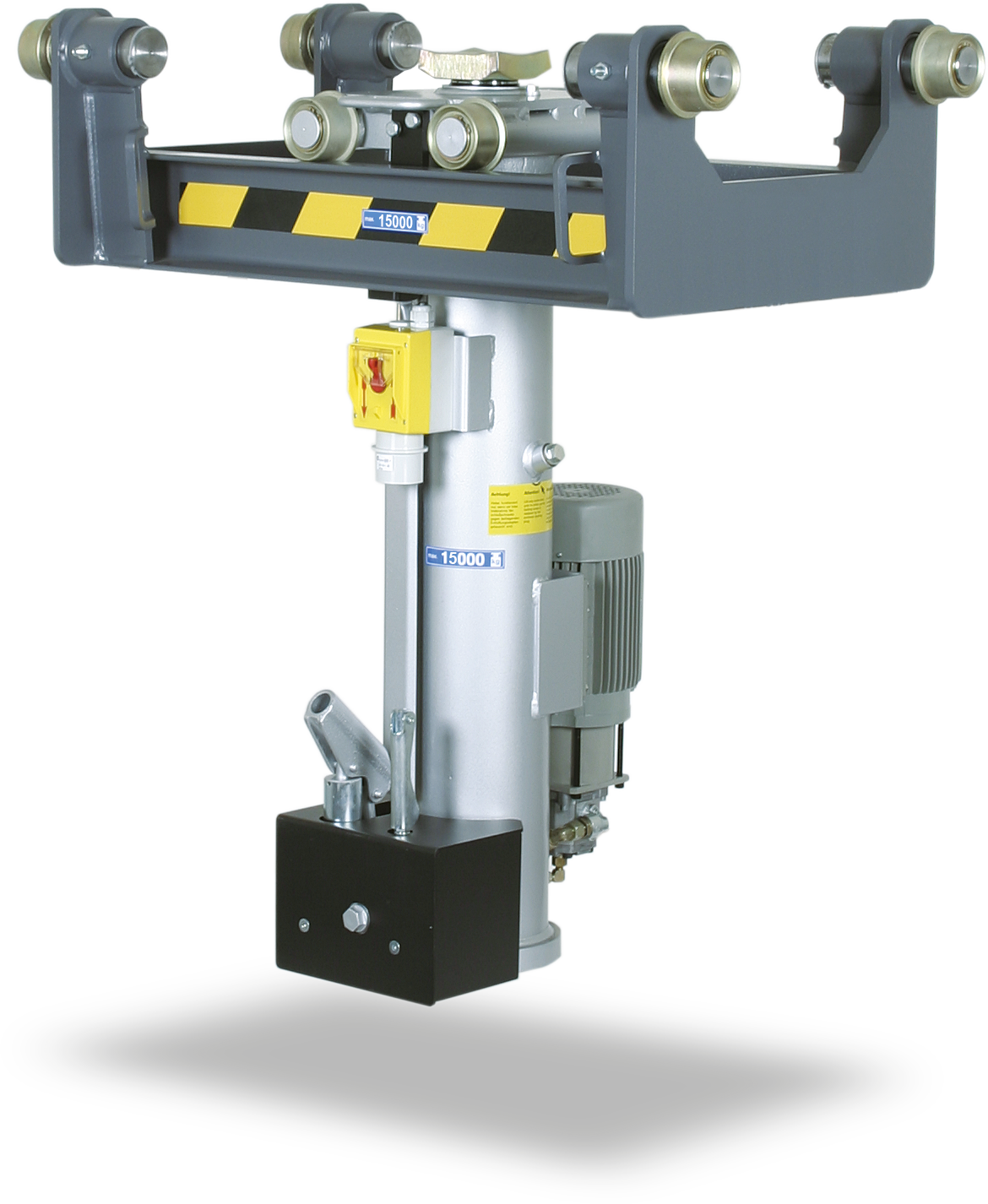

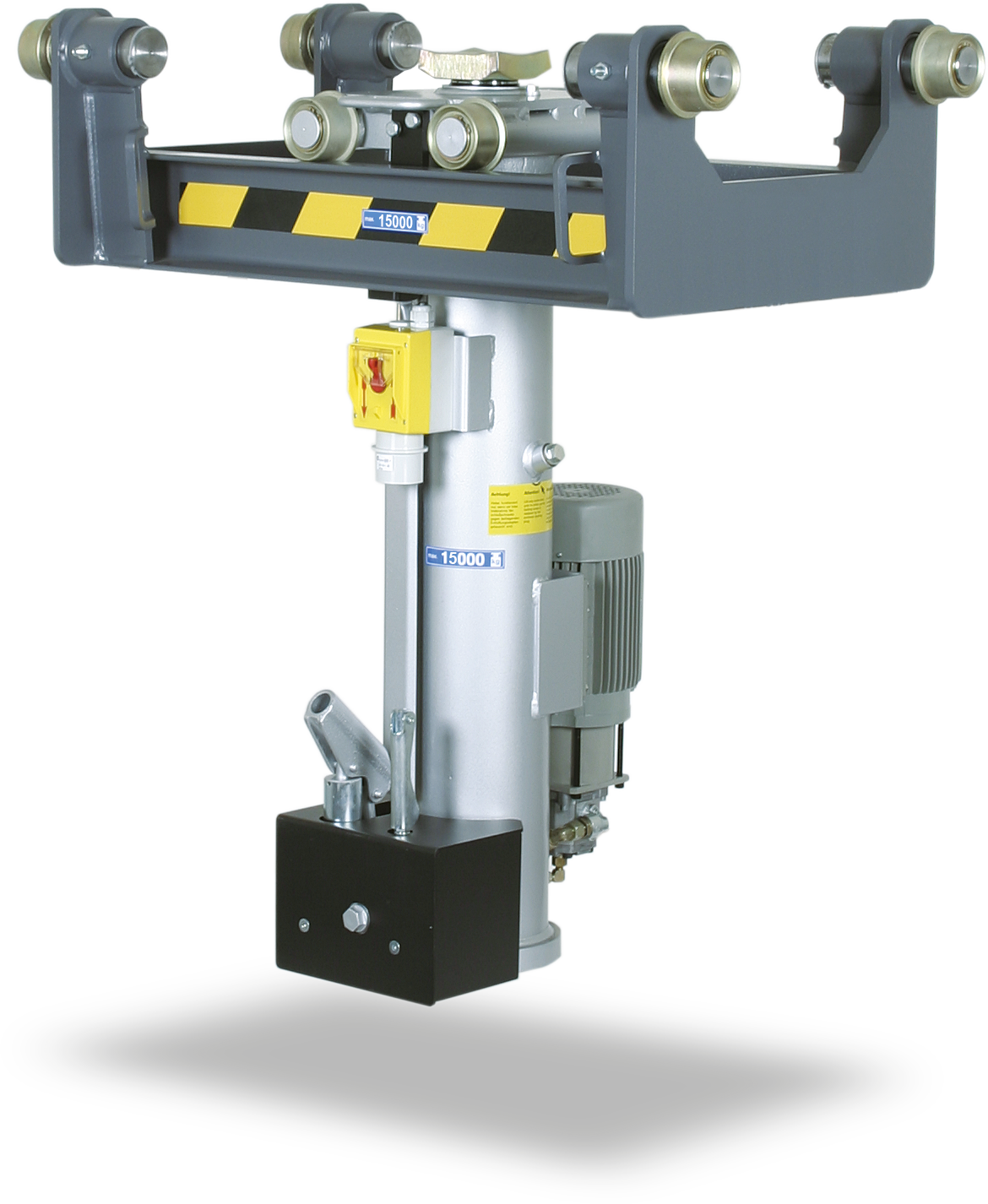

Pit lift, suspended GHUSLE 10

6 t, 800 mm stroke, Load stroke electro-hydraulic, hydraulic forced return of the lifting piston, smooth fine stroke by additional hydraulic hand pump

-

Pit lift, suspended GHUSLE 15

15 t, 800 mm stroke, Load stroke electro-hydraulic, hydraulic forced return of the lifting piston, smooth fine stroke by additional hydraulic hand pump

-

Pit lift, suspended GHUSLE 20

6 t, 800 mm stroke, Load stroke electro-hydraulic, hydraulic forced return of the lifting piston, smooth fine stroke by additional hydraulic hand pump

-

Pit lift, suspended GHUSLE 30

6 t, 800 mm stroke, Load stroke electro-hydraulic, hydraulic forced return of the lifting piston, smooth fine stroke by additional hydraulic hand pump

-

Gearbox lift Junior Jack 1,2 S2

1,2 t, 1100 mm stroke, air-hydraulic

-

Gearbox lift Junior Jack 2,0 S2

2.0 t, 1100 mm stroke, air-hydraulic

-

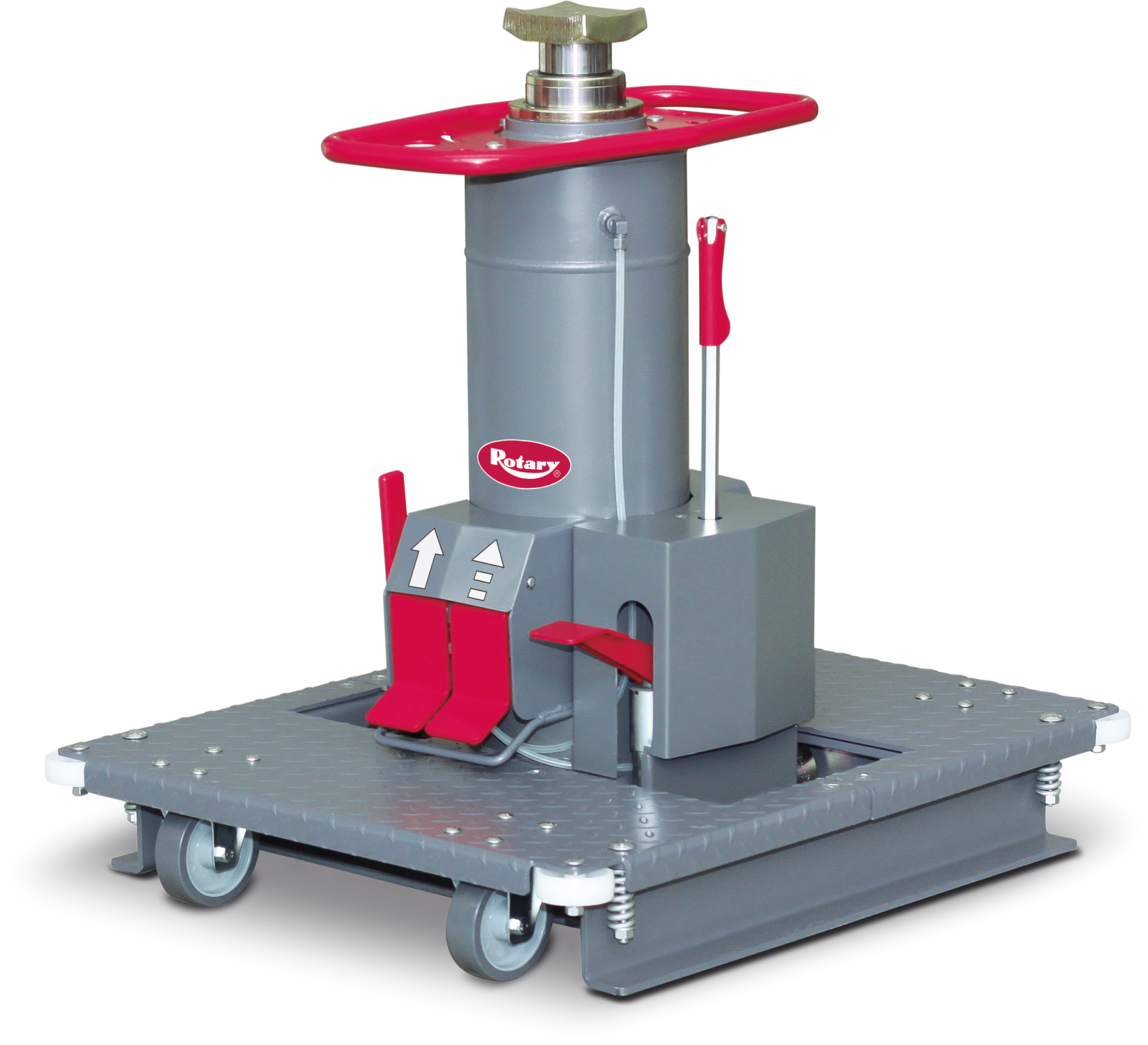

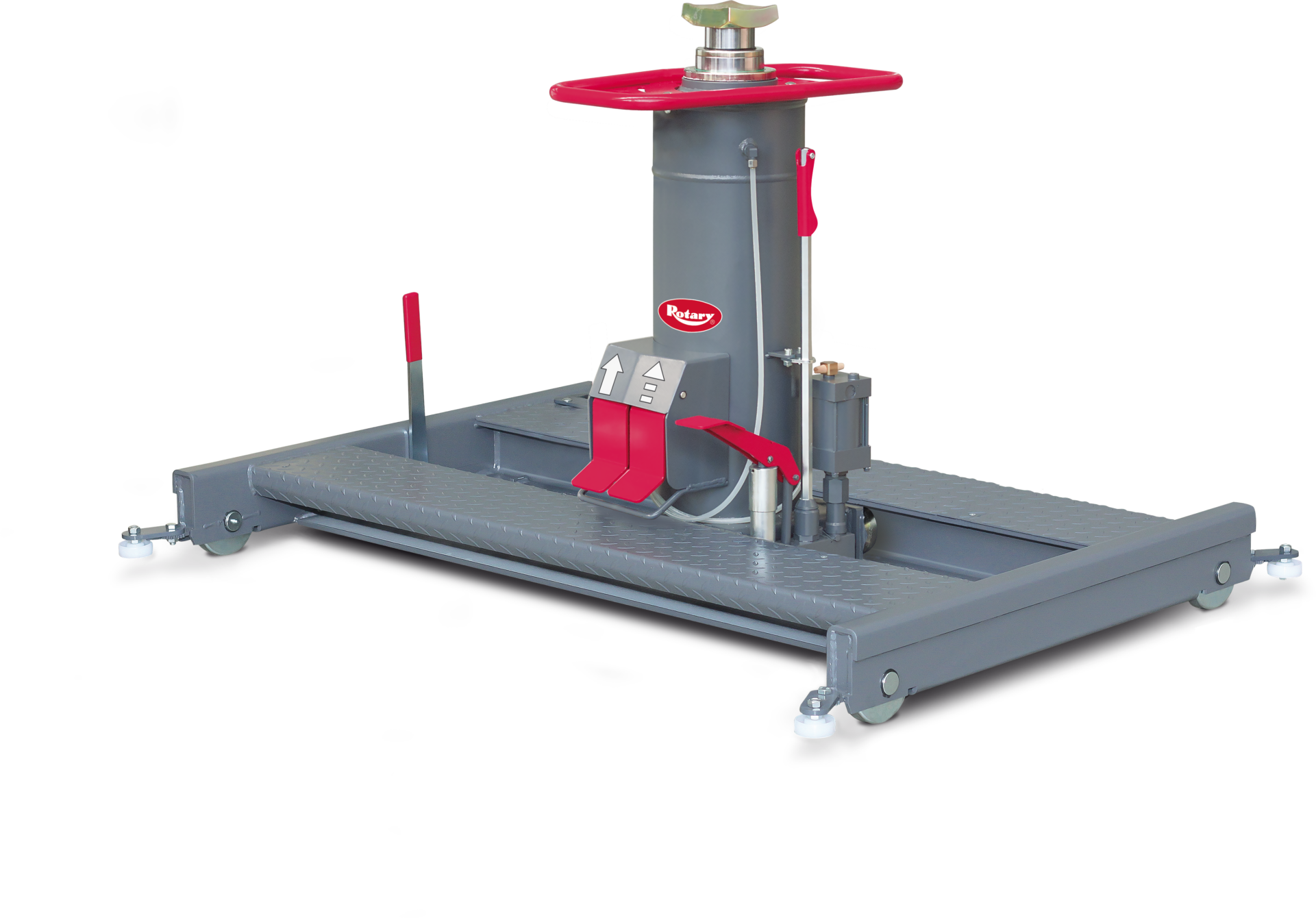

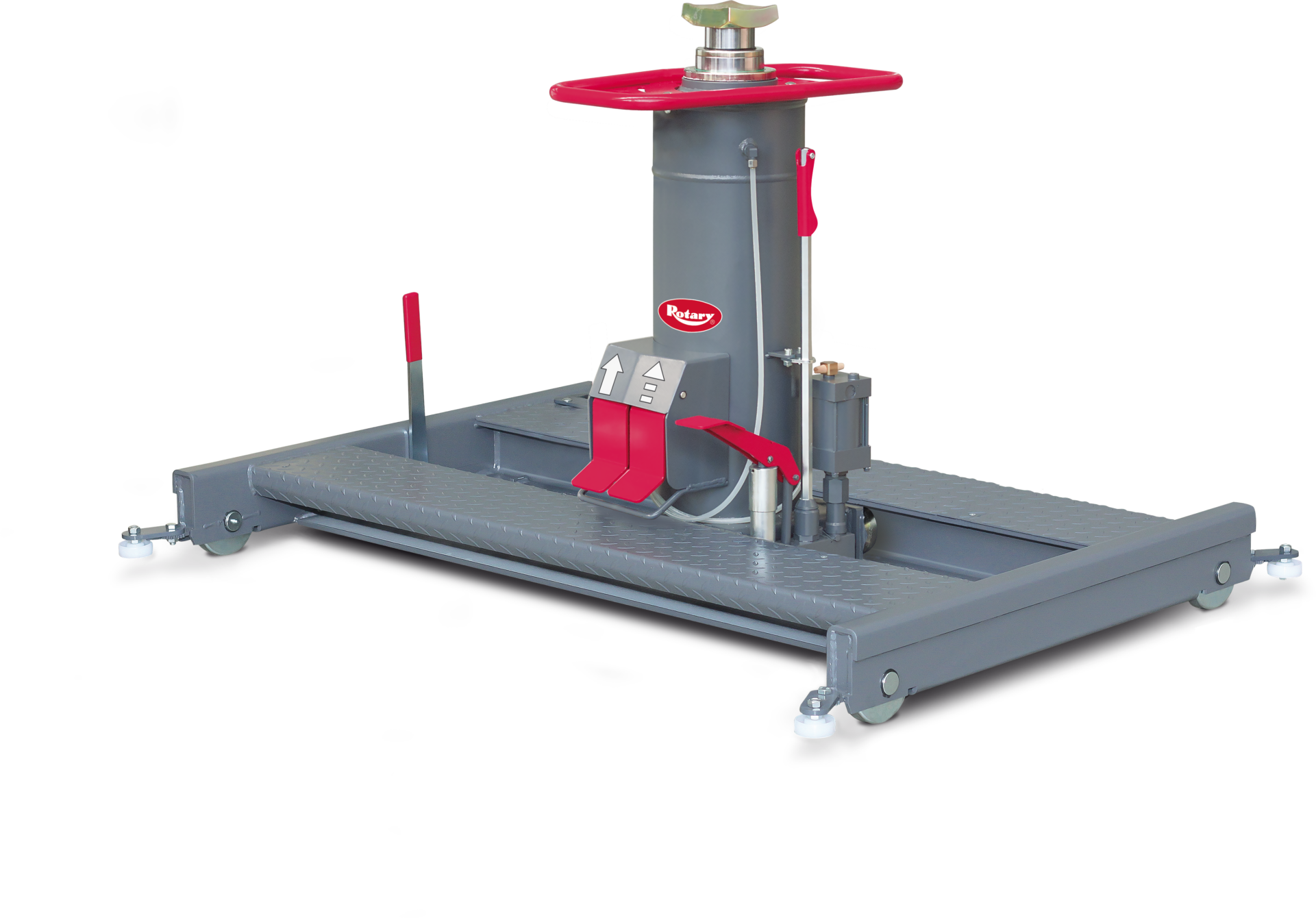

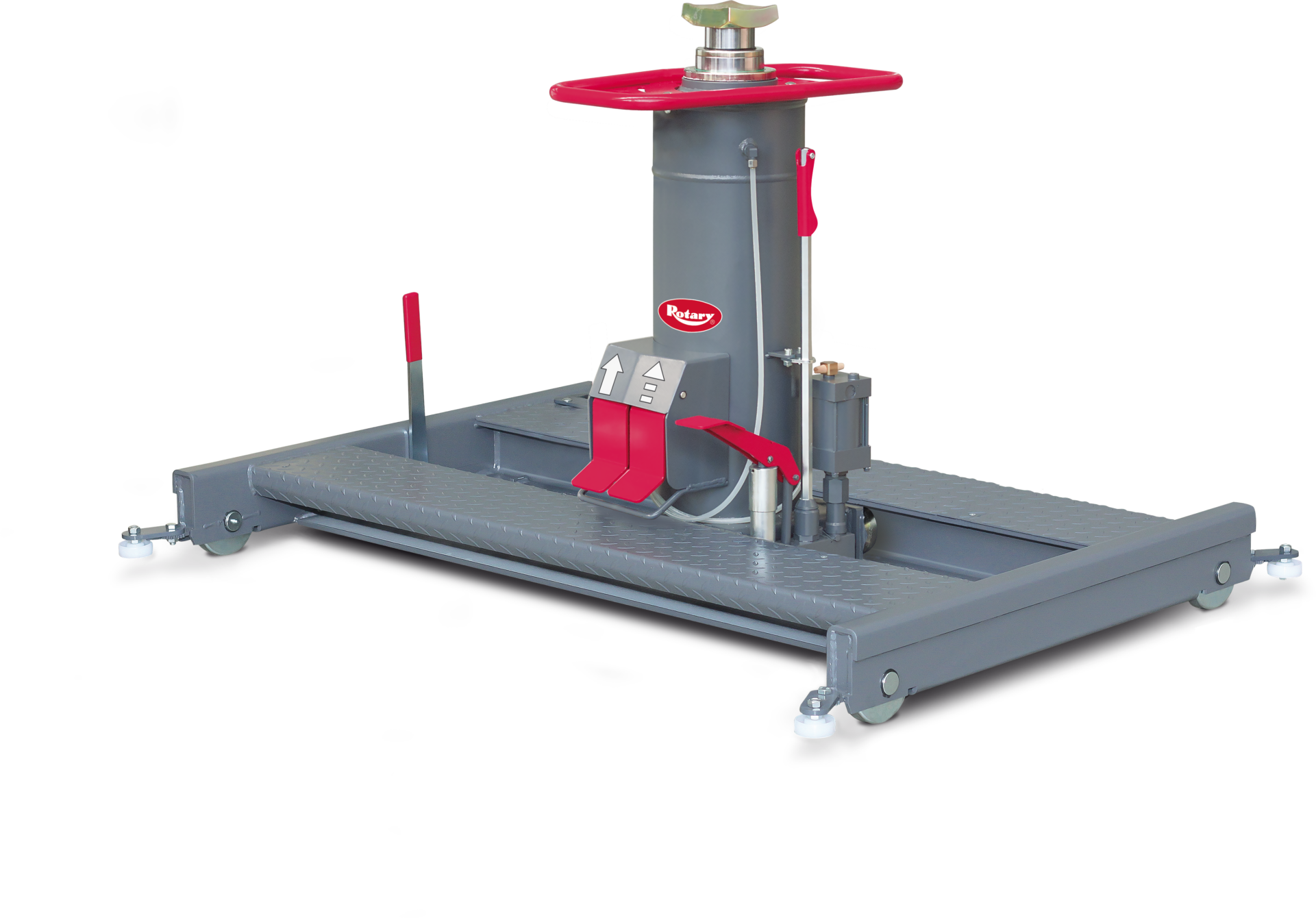

Gearbox lift Master Jack 2,5

2.5 t, 1100 mm stroke, air-hydraulic, foot control

-

Gearbox lift Master Jack 4,0

4.0 t, 1100 mm stroke, air-hydraulic, foot control

-

Jacking beam GHUSKTP 4/4

4/4 t, 330 mm stroke, air-hydraulic

-

Jacking beam GHUSKTP 6/6

6/6 t, 330 mm stroke, air-hydraulic

-

Jacking beam GHUSKTP 10/10

10/10 t, 330 mm stroke, air-hydraulic

-

Jacking beam GHUSKTP 12/12

12/12 t, 330 mm stroke, air-hydraulic

-

Jacking beam GHUSKTP 14/14

14/14 t, 330 mm stroke, air-hydraulic, centre axle jack, 2-fold telescopic, operating pressure 10 bar, peg Ø 55 mm

-

Tyre changer NAV73.17

Mounting head and mounting lever, fully automatic movement of the tool arm, 2 speeds (max. 8 rpm), cable console unit, truck, rim diameter 11 – 50″ (60″ with extension set), max. rim width 1750 mm | Red (RAL 3002)

-

Tyre changer NAV63.15BTH

Leverless, fully hydraulic movement of the tool arm, 2 speeds (max. 8 rpm), console unit with Bluetooth data transmission, truck, bus and agriculture, rim diameter 11 – 60″, max wheel width 1500 mm | Red (RAL 3002)

-

Tyre changer NAV63.15A

Leverless, fully hydraulic movement of the tool arm, 2 speeds (max. 8 rpm), hydraulic operating unit, truck, bus and agriculture, rim diameter 11 – 60″, max wheel width 1500 mm | Red (RAL 3002)

-

Tyre changer NAV43.15BTH

Leverless, fully automatic movement of the tool arm, 2 speeds (max. 8 rpm), console unit with Bluetooth data transmission, truck, rim diameter 11 – 43″ (56″ with extension set), max wheel width 1500 mm | Red (RAL 3002)

-

Tyre changer NAV43.15A

Leverless, fully automatic movement of the tool arm, 2 speeds (max. 8 rpm), hydraulic operating unit, truck, rim diameter 11 – 43″ (56″ with extension set), max wheel width 1500 mm | Red (RAL 3002)

-

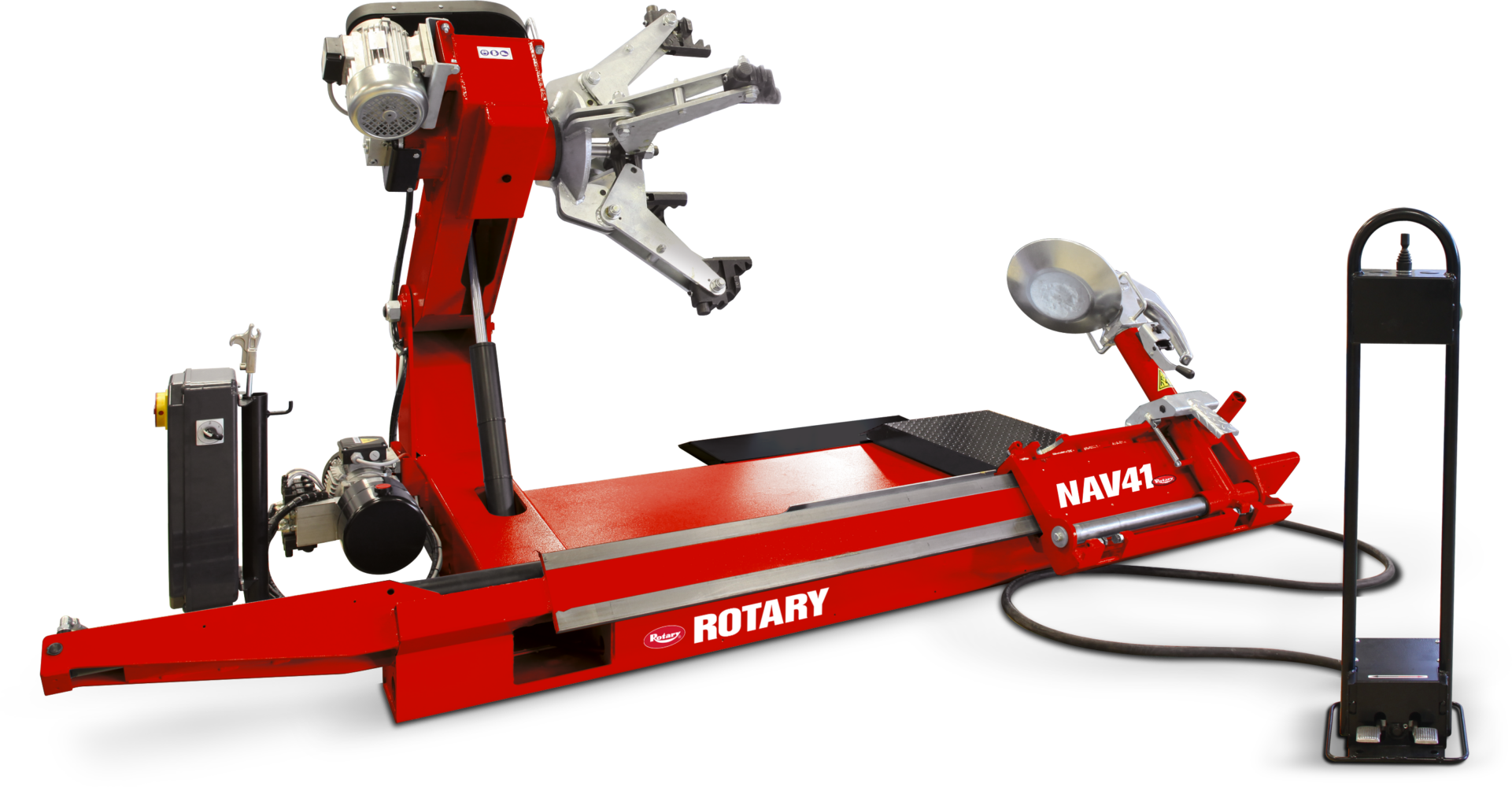

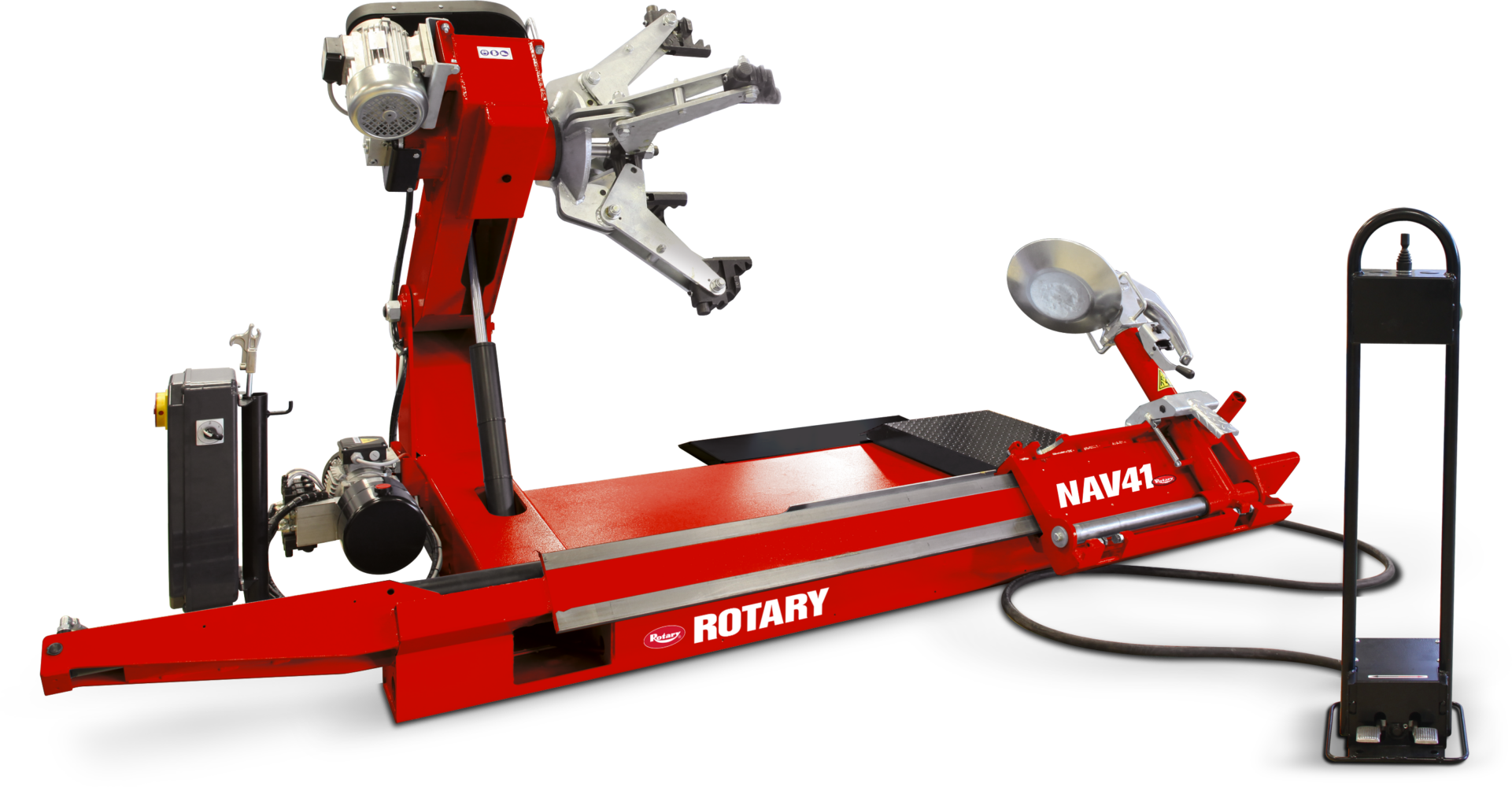

Tyre changer NAV43.15

Leverless, fully automatic movement of the tool arm, 2 speeds (max. 8 rpm), cable console unit, truck, rim diameter 11 – 43″ (56″ with extension set), max wheel width 1500 mm | Red (RAL 3002)

-

Tyre changer NAV101

Mounting head and mounting lever, for commercial vehicle tubeless tyres, synchronized double bead breaking, max. speed 8 rpm, hydraulic operating unit, truck, rim diameter 11 – 27″, max wheel width 540 mm | Grey (RAL 7016)

-

Tyre changer NAV26HW.TBTH

Mounting head and mounting lever, hydraulic operating unit with Bluetooth data transmission, suitable for portable use in vans, truck, rim diameter 11 – 27″, max wheel width 950 mm | Red (RAL 3002)

-

Tyre changer NAV63.15

Leverless, fully hydraulic movement of the tool arm, 2 speeds (max. 8 rpm), cable console unit, truck, bus and agriculture, rim diameter 11 – 60″, max wheel width 1500 mm | Red (RAL 3002)

-

Tyre changer NAV51.15

Mounting head and mounting lever, fully automatic movement of the tool arm, 2 speeds (max. 8 rpm), cable console unit, truck, rim diameter 11 – 43″ (56″ with extension set), max wheel width 1500 mm | Red (RAL 3002)

-

Tyre changer NAV41.13EI 400 V – 3 Ph – 50 Hz

Mounting head and mounting lever, Quick-Fit system mounting tool, double speed for chucking table rotation, cable console unit, truck, bus, agricultur and small EM, rim diameter 11 – 43″ (56″ with extension set), max wheel width 1100 mm | Red (RAL 3002)

-

Tyre changer NAV41.13EI 220 V – 3 Ph – 60 Hz

Mounting head and mounting lever, Quick-Fit system mounting tool, double speed for chucking table rotation, cable console unit, truck, bus, agricultur and small EM, rim diameter 11 – 43″ (56″ with extension set), max wheel width 1100 mm | Red (RAL 3002)

-

Tyre changer NAV41.11N

Mounting head and mounting lever, Quick-Fit system mounting tool, double speed for chucking table rotation, hydraulic operating unit, truck, bus, agricultur and small EM, rim diameter 11 – 43″ (56″ with extension set), max wheel width 1100 mm | Red (RAL 3002)

-

Tyre changer NAV11N 400 V – 3 Ph – 50 Hz

Mounting head and mounting lever, Quick-Fit system mounting tool, hydraulic operating unit, truck, bus and agriculture, rim diameter 11 – 27″, max wheel width 925 mm | Red (RAL 3002)

-

Tyre changer NAV11N 230 V – 1 Ph – 50 Hz

Mounting head and mounting lever, Quick-Fit system mounting tool, hydraulic operating unit, truck, bus and agriculture, rim diameter 11 – 27″, max wheel width 925 mm | Red (RAL 3002)

-

Tyre changer NAV101 400 V – 3 Ph – 50 Hz

Mounting head and mounting lever, for commercial vehicle tubeless tyres, synchronized double bead breaking, max. speed 8 rpm, hydraulic operating unit, truck, rim diameter 11 – 27″, max wheel width 540 mm | Red (RAL 3002)

-

Tyre changer NAV101 400 V – 3 Ph – 60 Hz

Mounting head and mounting lever, for commercial vehicle tubeless tyres, synchronized double bead breaking, max. speed 8 rpm, hydraulic operating unit, truck, rim diameter 11 – 27″, max wheel width 540 mm | Red (RAL 3002)

-

Tyre changer NAV101 230 V – 3 Ph – 50 Hz

Mounting head and mounting lever, for commercial vehicle tubeless tyres, synchronized double bead breaking, max. speed 8 rpm, hydraulic operating unit, truck, rim diameter 11 – 27″, max wheel width 540 mm | Red (RAL 3002)

-

Tyre changer NAV26HW.T

Mounting head and mounting lever, cable hydraulic operating unit, suitable for portable use in vans, truck, rim diameter 11 – 27″, max wheel width 950 mm | Red (RAL 3002)

-

Tyre changer NAV26HW

Mounting head and mounting lever, hydraulic operating unit on a fixed column, suitable for installation in closed vans, truck, rim diameter 11 – 27″, max wheel width 950 mm | Red (RAL 3002)

-

Electronic wheel balancer Librak338FMD

Backlit LCD graphic display (132 x 40 mm), automatic detection of distance and diameter, automatic cycle, wheel brake, incl. cones for cars, wheel hood and handwheel quickfit nut, passenger car, rim diameter 10 – 26″ | Red (RAL 3002)

-

Wheel balancer Librak240RTLCD

Backlit LCD graphic display (132 x 40 mm), automatic cycle, incl. cones for trucks (Ø 202 – 221 mm, 281 mm), adapter, handwheel nut and wheel lift (200 kg), truck, rim diameter 10 – 26″ | Red (RAL 3002)

-

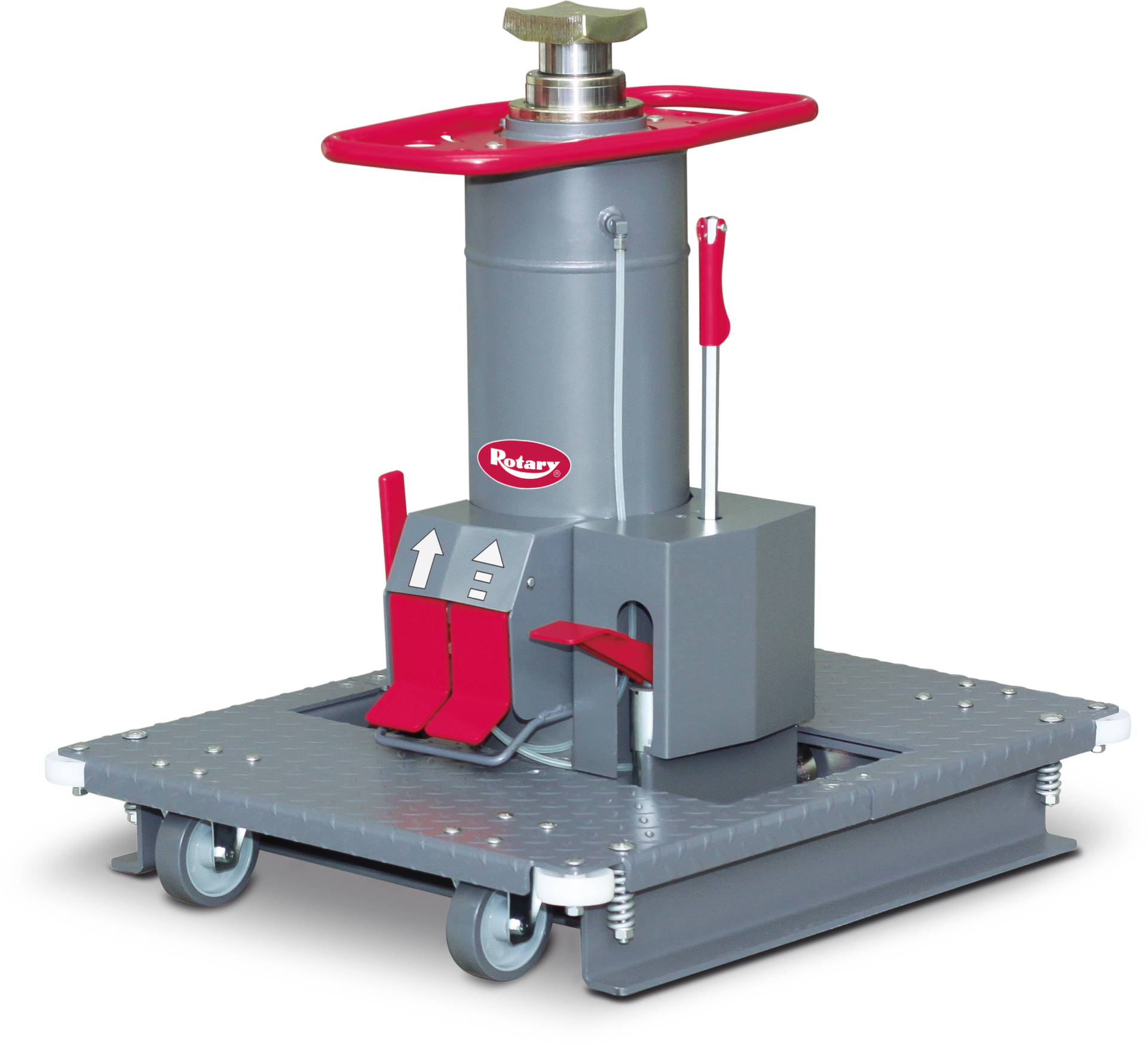

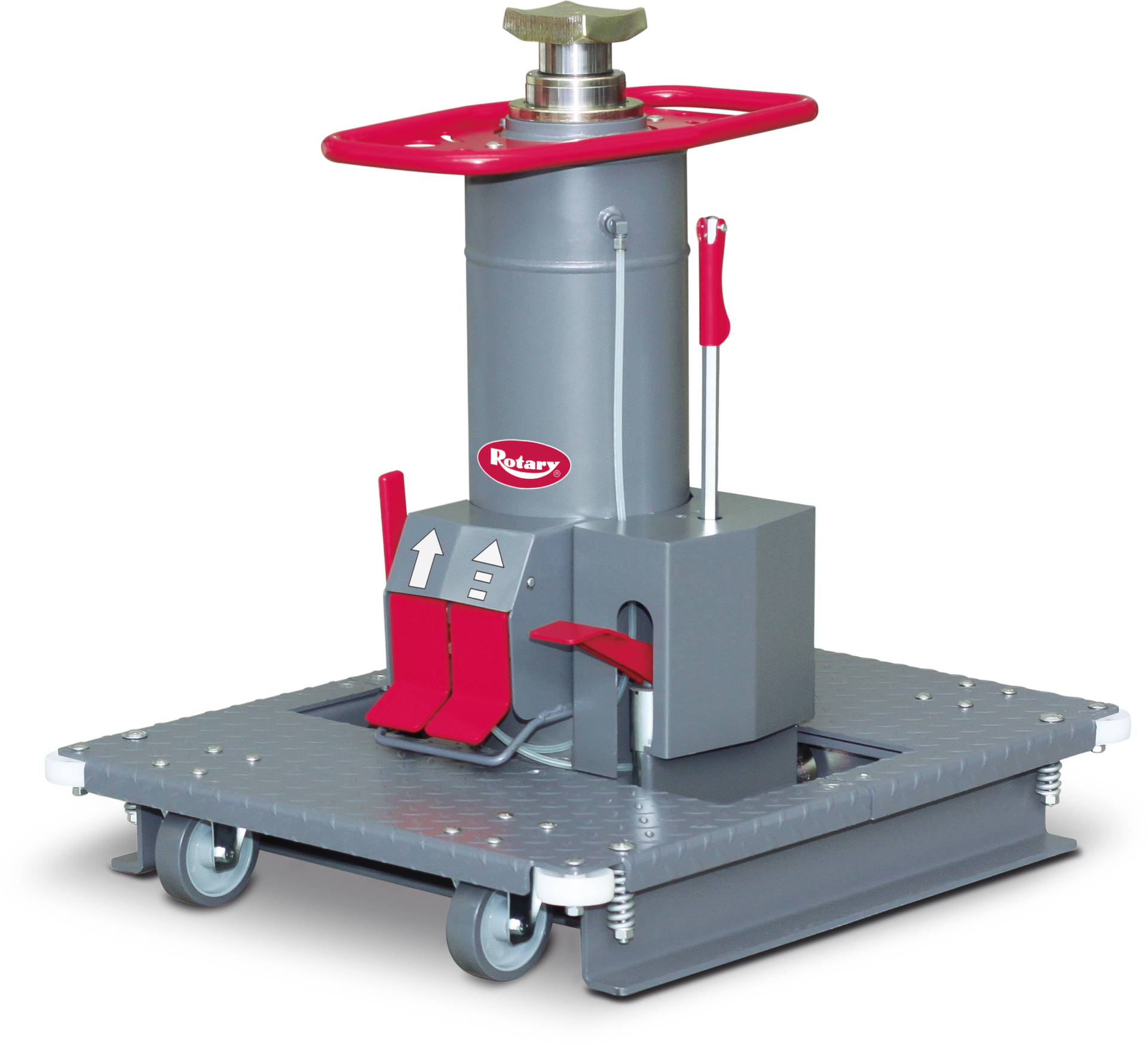

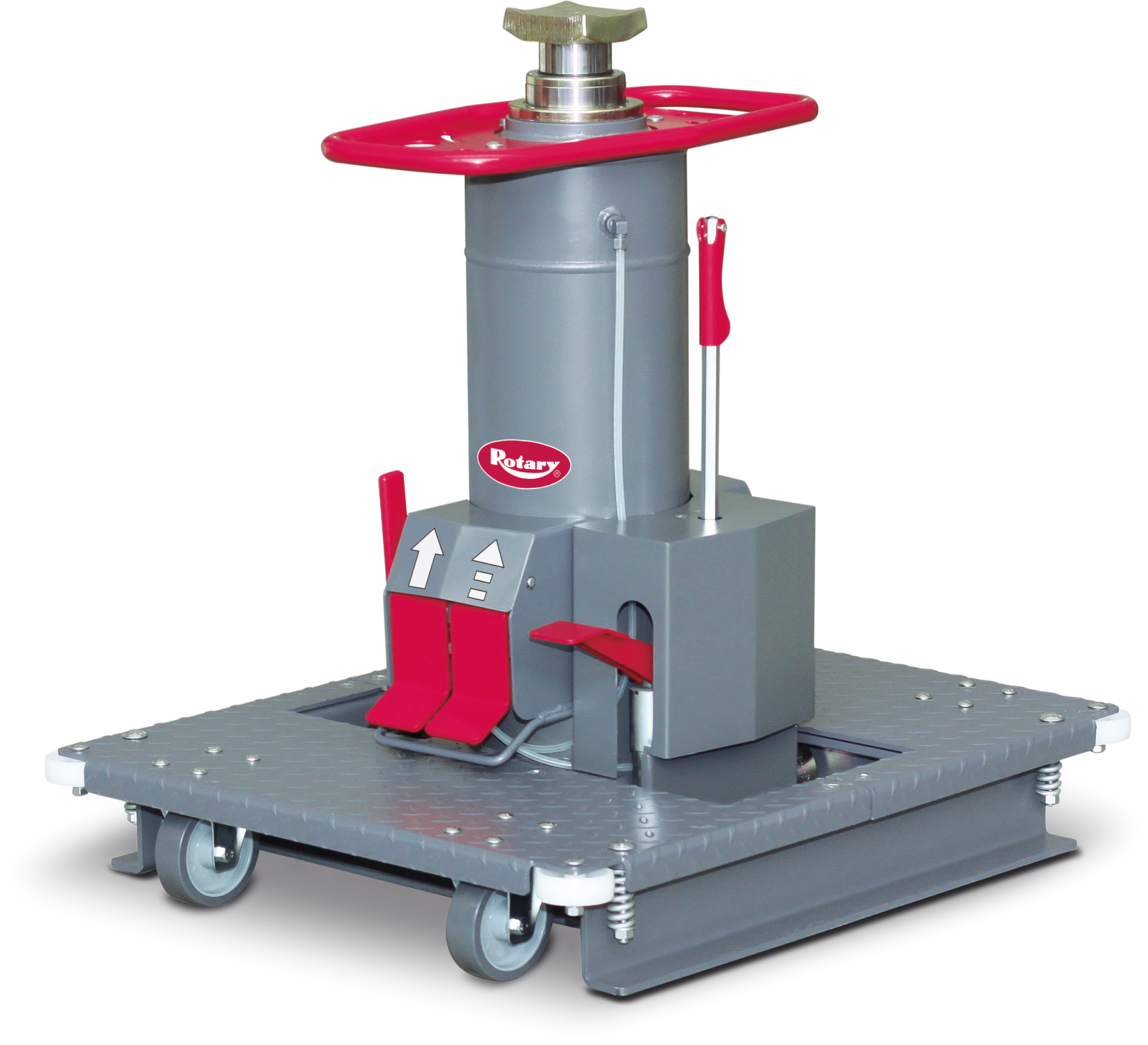

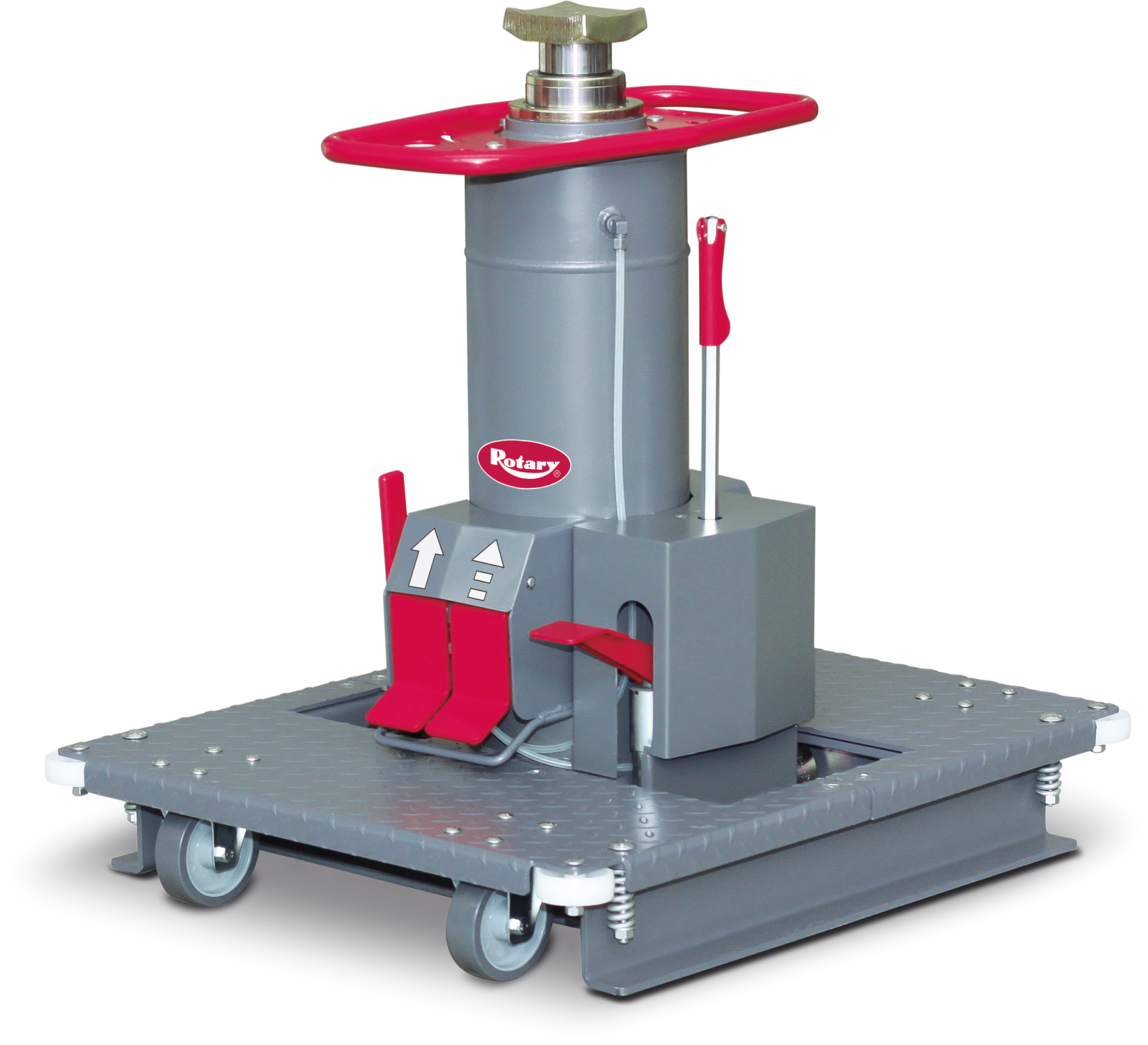

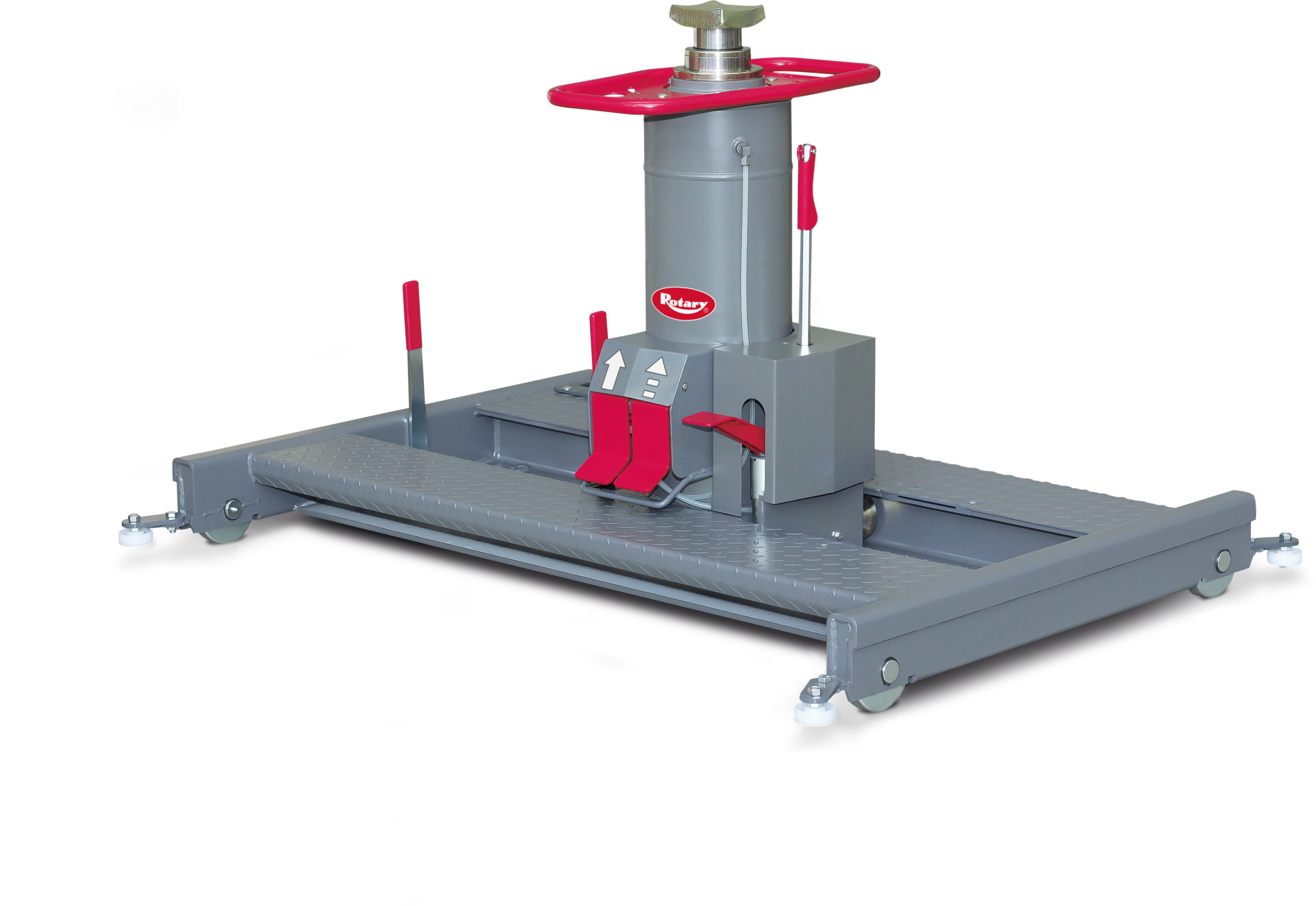

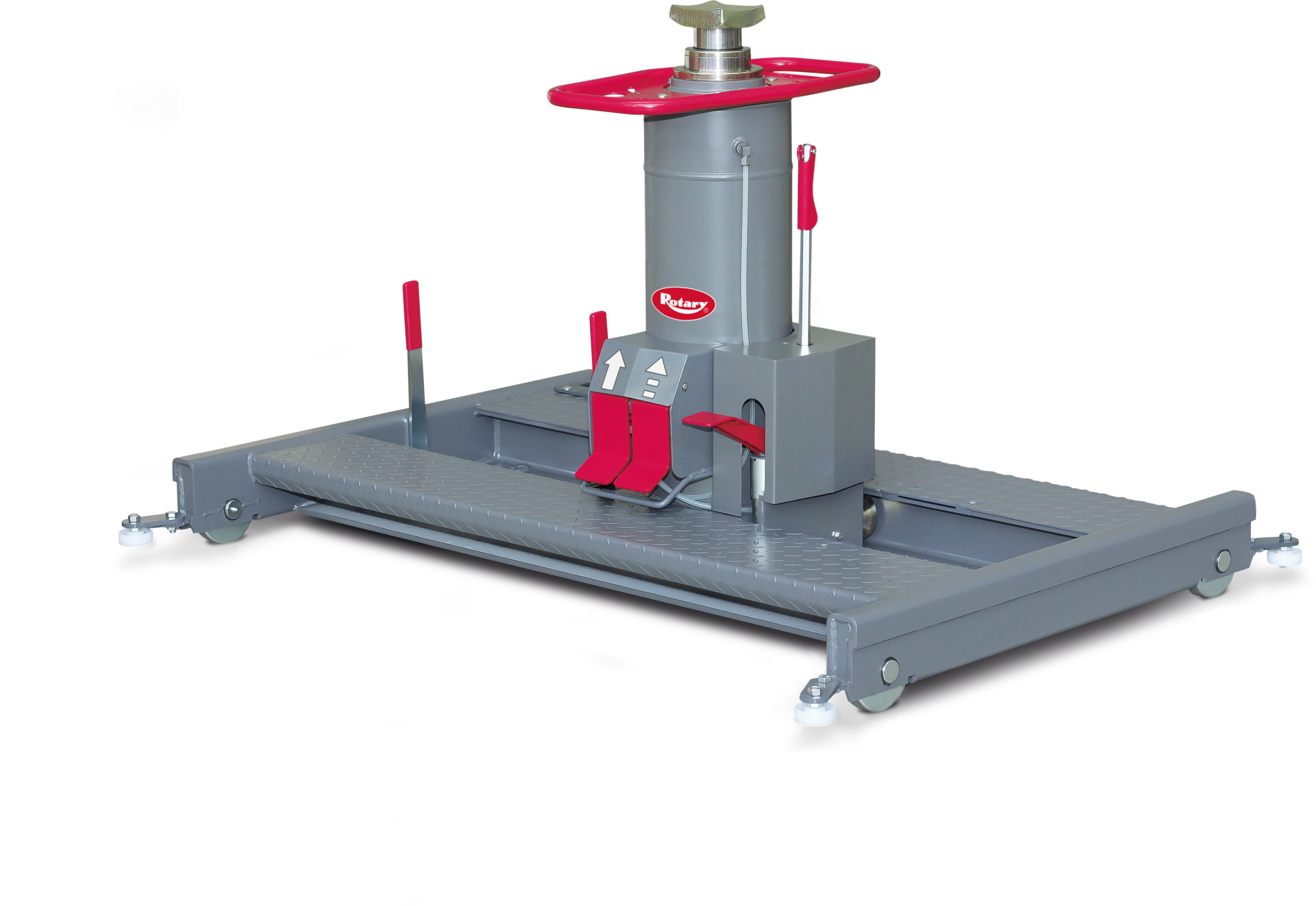

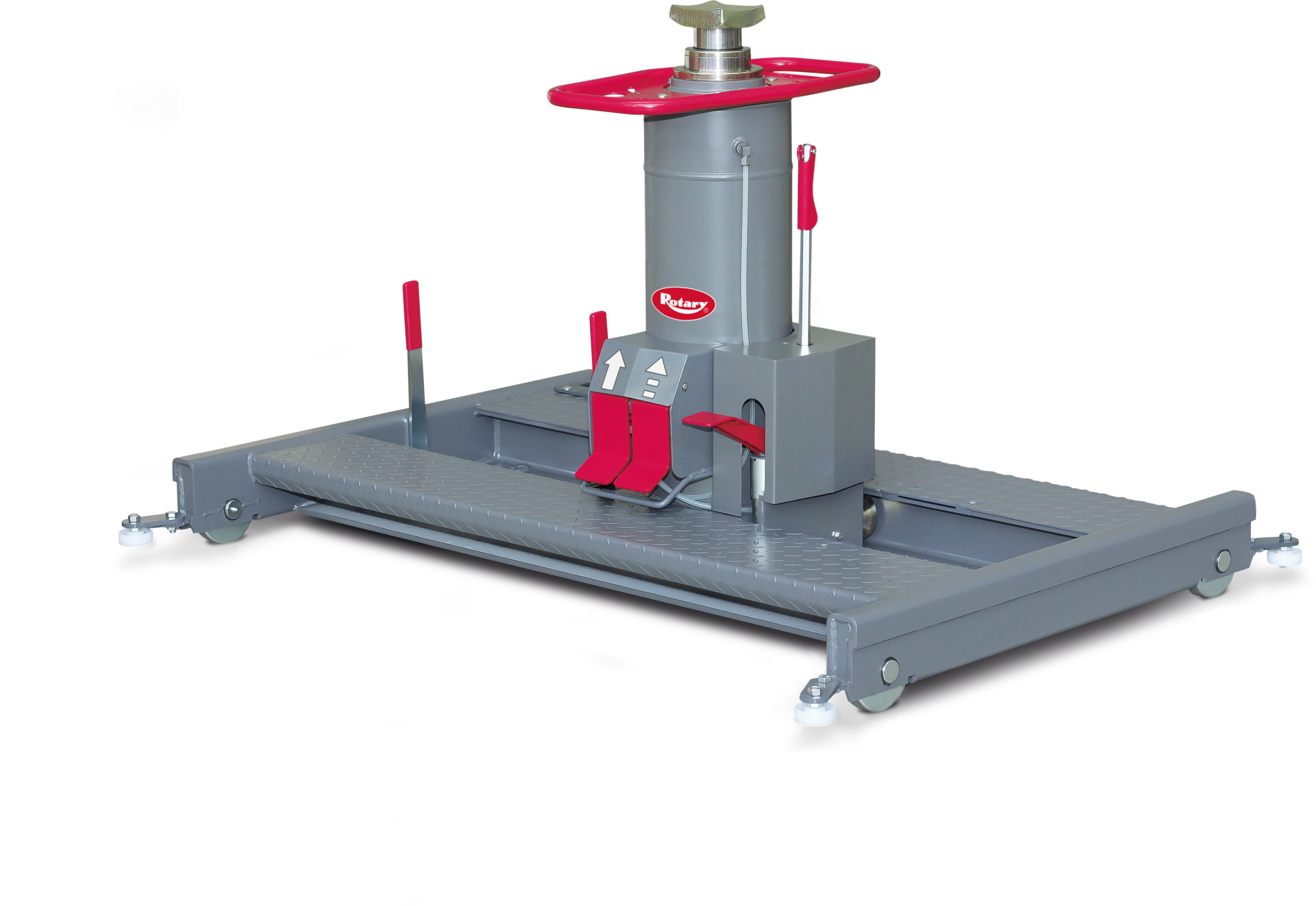

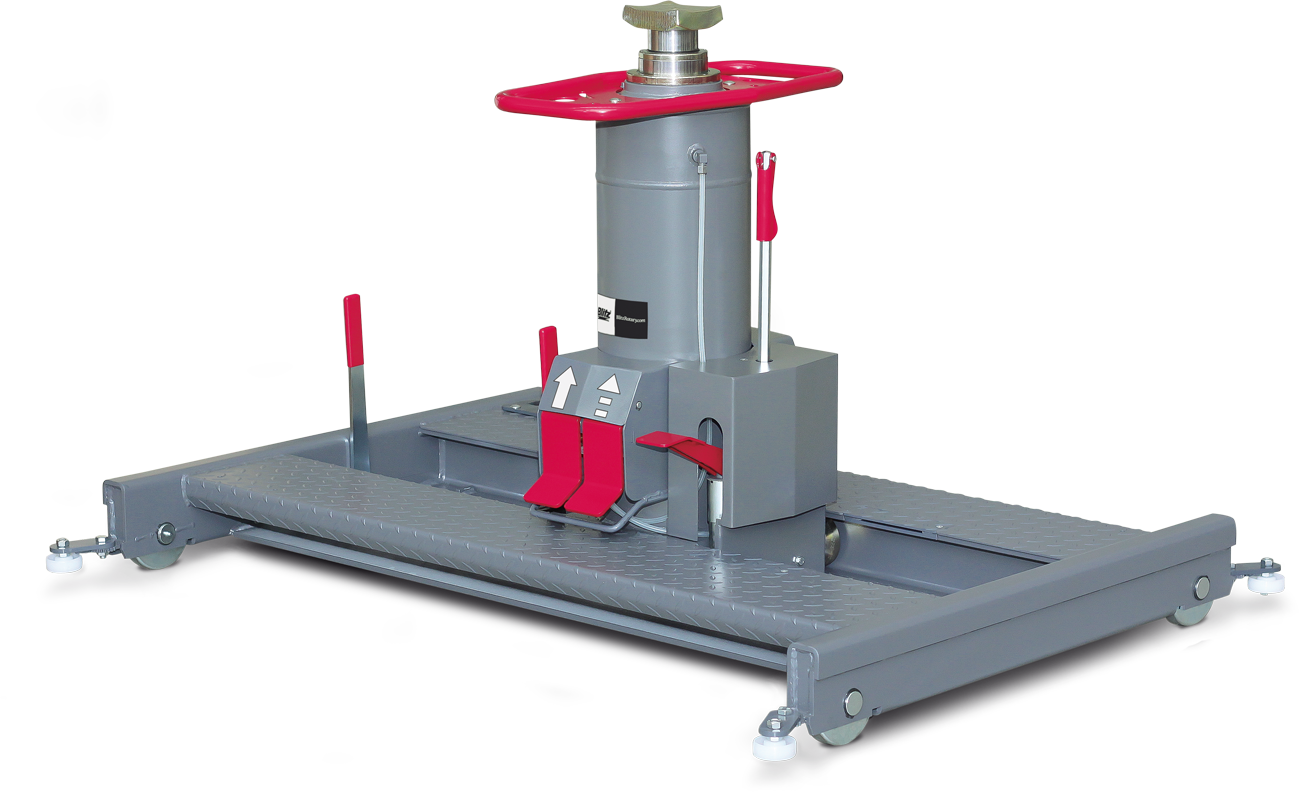

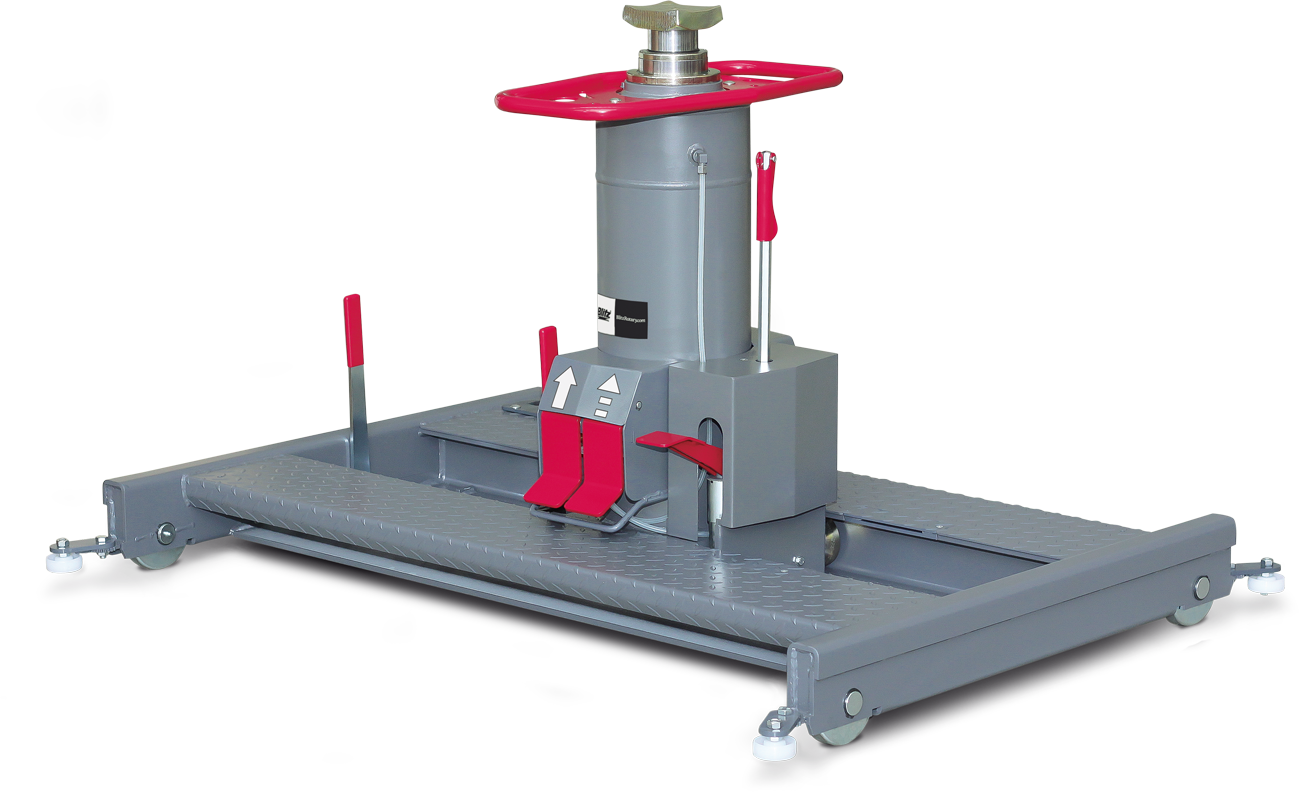

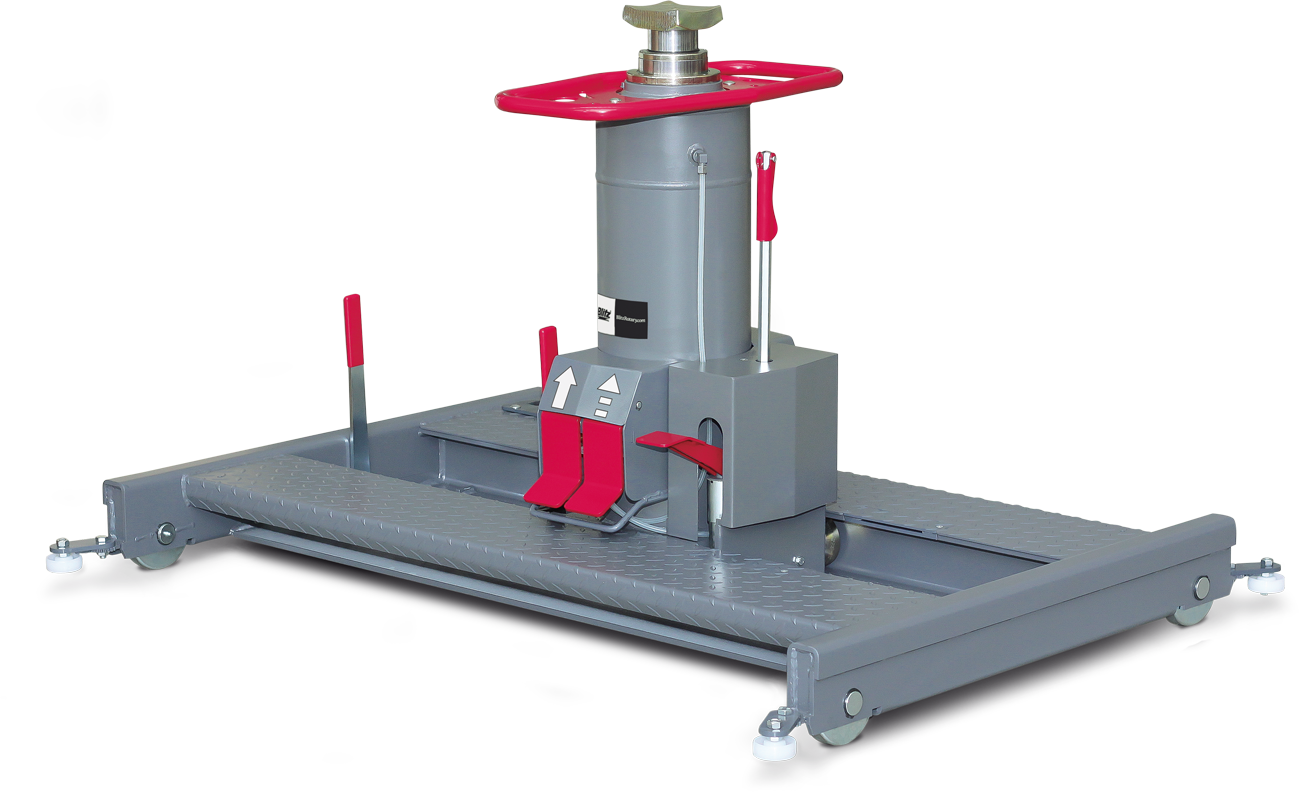

Lifting table MGE 2.0

2.0 t, 1000 mm stroke, air hydraulic pump | Grey (RAL 7015)

-

Wheel balancer Librak280RTLC Pro

22″ full HD LCD monitor, industrial PC, automatic detection of distance and diameter, automatic cycle, incl. cones for trucks (Ø 202 – 221 mm, 281 mm), adapter, handwheel nut and wheel lift (200 kg), truck, im diameter 10 – 26″ | Red (RAL 3002)

-

CCD wheel aligner RWA5100HDB.3

2 portable boxes, CCD wheel aligner for trucks, with 6 lowered CCD sensors, 3-point wheel clamps, cylinder adapter kit, 12″ LCD Windows tablet, wheeled suitcase with external power plug and cord

-

CCD wheel aligner SPEED8080PTWSR.4

8 CCD truck wheel aligner, with lowered sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8080PTWSR.4 (grey)

8 CCD truck wheel aligner, with lowered sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8080PTWS.4

8 CCD truck wheel aligner, with standard sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8080PTWS.4 (grey)

8 CCD truck wheel aligner, with standard sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8060PTWSR.4

6 CCD truck wheel aligner, with lowered sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8060PTWSR.4 (grey)

6 CCD truck wheel aligner, with lowered sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8060PTWS.4

6 CCD truck wheel aligner, with standard sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8060PTWS.4 (grey)

6 CCD truck wheel aligner, with standard sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8080PTWSR.3

8 CCD truck wheel aligner, with lowered sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8080PTWSR.3 (grey)

8 CCD truck wheel aligner, with lowered sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8080PTWS.3

8 CCD truck wheel aligner, with standard sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8080PTWS.3 (grey)

8 CCD truck wheel aligner, with standard sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8060PTWSR.3

6 CCD truck wheel aligner, with lowered sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner SPEED8060PTWS.3

6 CCD truck wheel aligner, with standard sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner RWA5100HD.3

6 CCD truck wheel aligner, with lowered sensors | incl. 3-point clamps (2 x STDA92), 2 Turntables (STDA29L), open cabinet, 11.6″ LCD Windows tablet, press pedal and steering lock | 1 x 230 V / 50 – 60 Hz

-

CCD wheel aligner RWA5100HD

6 CCD truck wheel aligner, with lowered sensors | incl. open cabinet, 11.6″ LCD Windows tablet, press pedal and steering lock | 1 x 230 V / 50 – 60 Hz

-

Air receiver K 1000/11

11 bar, lacquered, horizontal execution

-

Air receiver K 1000/11

11 bar, galvanised, horizontal execution

-

Air receiver K 1000/16

16 bar, lacquered, horizontal execution

-

Air receiver K 1000/16

16 bar, galvanised, horizontal execution

-

Air receiver K 1500/11

11 bar, galvanised, horizontal execution

-

Air receiver K 1500/16

16 bar, lacquered, horizontal execution

-

Air receiver K 250/11

11 bar, lacquered, horizontal execution

-

Air receiver K 250/11

11 bar, galvanised, horizontal execution

-

Air receiver K 250/16

16 bar, lacquered, horizontal execution

-

Air receiver K 250/16

16 bar, galvanised, horizontal execution

-

Air receiver K 350/11

11 bar, lacquered, horizontal execution

-

Air receiver K 350/11

11 bar, galvanised, horizontal execution

-

Air receiver K 350/16

16 bar, lacquered, horizontal execution

-

Air receiver K 350/16

16 bar, galvanised, horizontal execution