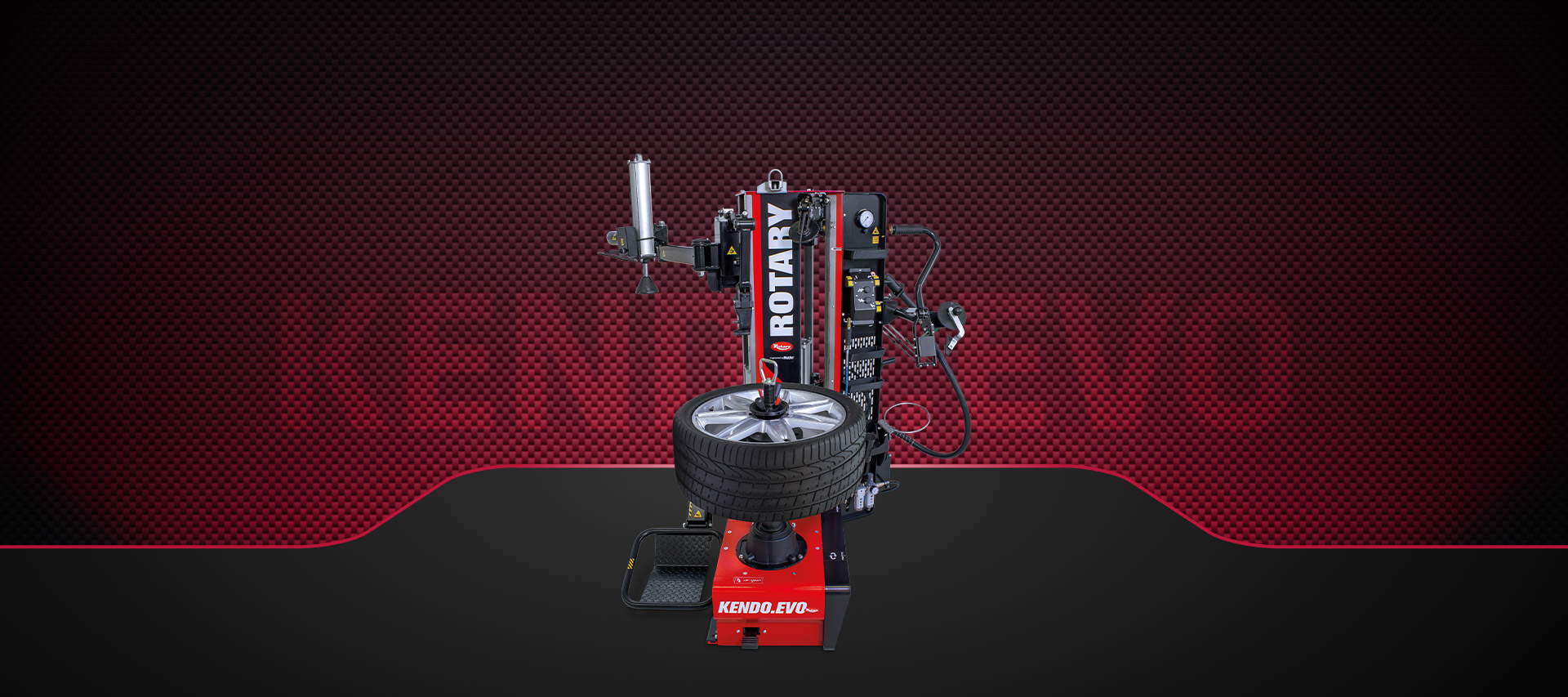

VSG launches the new Kendo.Evo tyre changer for the Rotary brand

For years the Kendo range has been the choice of workshops searching for a product offering high performance and technological precision. This is a certainty that VSG wants to further consolidate by also giving Kendo.Evo a sophisticated design, in line with the most recent market developments.

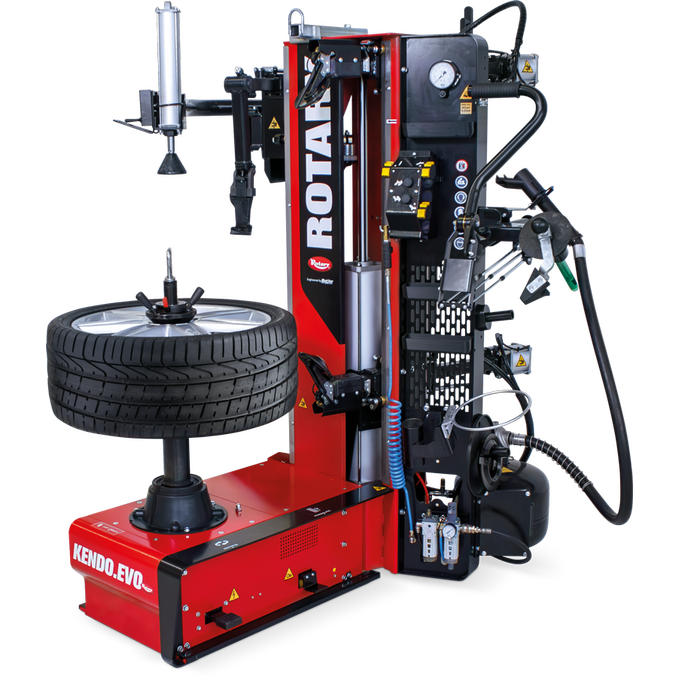

The new Kendo.Evo is the result of an in-depth assessment of the dynamics and greater difficulties that arise inside workshops, with the aim of identifying a solution that can meet the requirements of any type of operator. This work was performed together with the end user through surveys and practical work sessions.

What are the new design features introduced in the Kendo.Evo?

Large storage area that can be modulated based on the operator’s characteristics and re-quirements.

The operator has at his disposal a grid he can position containers according to his personal working method, his personal physical characteristics and/or the set-up of the work space available.

Rounded frame shapes that ensure easier movements.

The operator is able to easily work around the machine limitation-free and without the fear of impacts.

Immediately understandable symbols that guide the operations.

Every machine function is displayed using symbols that make the work process even faster.

Notwithstanding attention to the operator can be considered the crux of product development, the technological aspect was not given less importance. This characteristic distinguishes the range com-pared to the other solutions found on the market.

- Without the need for any adjustment, the frame lets the operator work on 12” to 30” rims, with the expected increase in average diameter of rims due to the increased number of electric vehicles being anticipated.

- Patented mounting head in scratchproof material for working near the edge of the rims with-out damaging them and without causing any stress harmful to the tyre bead.

- Extra grip plate – the floating movement of the plate makes locking the tyre fast and effortless due to the easy positioning of the centring cone, in this way simplifying a fundamental oper-ation.

- Proximity sensors automatically activate the radial penetration movement, making tyre bead breaking easier.